To prevent unfavorable conditions, dampproofing is crucial for residential locations vulnerable to water infiltration, such as the basement, kitchen, bathroom, balcony areas, water tank, etc. Continue reading to learn more about this technique’s many kinds of procedures.

Post your Requirement

What is Waterproofing?

The process of waterproofing involves creating an impenetrable barrier over the surface of structural parts such as walls, roofs, and foundations. The impervious barrier’s purpose is to keep water from penetrating. Surfaces of buildings are often made waterproof and water-resistant.

It is a preventative measure that renders a surface water-resistant and stops liquids from entering undesirable surfaces under external factors such as hydrostatic pressure and capillarity.

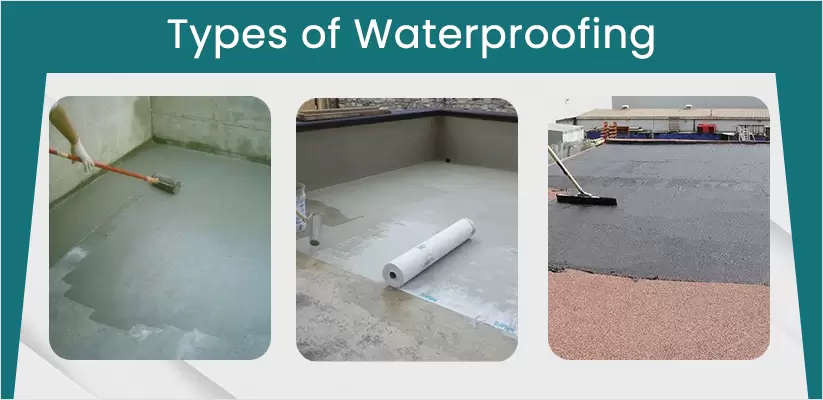

Types of Waterproofing commonly used in India.

Choosing the best technique is essential for sealing your home against water damage. Below are some of the types commonly used in unfiltered areas.

- Cementitious Waterproofing

Although this kind of technique is rigid, it does not matter because it is not subject to any weathering. It is mainly employed in moist interior areas of structures. It is the simplest way to process since the process is simpler and the materials needed are more readily available.

- Liquid Waterproofing Membrane

Two topcoats and a primer coat make up the liquid membrane. The coatings can be applied with a sprayer, roller, or trowel. The liquid layer is thin than cementitious varieties and gives greater flexibility. On the wall, the liquid hardens into a flexible layer. The ability of the coat to lengthen can rise by as much as 280%.

- Bituminous Coating Waterproofing

It is typically applied on concrete surfaces. The bituminous coating shouldn’t be applied to surfaces that receive direct sunlight because the coating weakens with time and becomes more susceptible to damage. It is used with other materials, such as acrylic-based polymers, to overcome this problem.

- Bituminous Membrane Waterproofing

A flashlight and a self-adhesive membrane are employed in this standard approach, which is used for low-sloped roofs because of their inefficiency. The quality of the polymer grade and the fiber from which it is made might impact the product’s flexibility and water resistance.

- Polyurethane Liquid Membrane Waterproofing

This technique is applied to flat roof areas and insulates the roof from the elements. It is also inexpensive compared to other types, making it so popular. Liquid polyurethane membranes that are extremely flexible are made to resist outside influences. Polyurethane membranes must be applied with the knowledge that they are moisture-sensitive.

Common Products Used for Waterproofing.

- Polyurethane: This substance is used on exposed surfaces and to waterproof roofs. This is one of the priciest chemical techniques on the market.

- Polyurea: Regarding protective coatings, polyurea is regarded as one of the most flexible, durable, and strong materials available.

- Bituminous: The ideal material for water-tightening concrete foundations is bituminous, sometimes referred to as asphalt coatings.

- Poly acrylic: One of the most popular and best characteristics of water sealing material for concrete structures is this. This substance is used to waterproof terraces and to seal leaks in walls.

- Grout and epoxy: This substance can be applied to functioning structures that have acquired cracks. These substances must be injected into the fractures or the surface by drilling holes.

Signs that the area needs waterproofing.

If your facility exhibits any of the warning indicators listed below, you should know that it needs this process:

- Damp and wet walls

- growth of fungus and mold

- corroded signs

- Pooling water

- Water dripping from the ceiling or roof

Additionally, all of these issues can potentially damage the building’s interiors and the structure’s core.

Areas where waterproofing is a must.

- Water treatment plants

- Dams

- Railway and subway systems

- Bridges

- Marine cargo ports and docks

- River locks/channels

- Sewage treatment facilities

- Parking structures

- Tunnels

The science behind waterproofing and how it works?

Concrete’s different chemicals and moisture react with the ingredients to create insoluble crystals that seal the capillaries, fissures, and pores. Unlike membrane coatings, this crystalline formation is not affected by environmental variables because it is embedded into the concrete. It is typically put over the floor slab and underneath the final tiles to prevent water from penetrating the slab.

To prevent water leaks, chemical reactions, heat, and other substances from coming into touch with the surface underlay, a waterproof seals the surface. To provide a longer-lasting construction, it can withstand wearing, tearing, and breaking and even releases water vapor into the atmosphere.

Waterproofing Steps you should Follow

- Step 1: The walls of your house are ground smooth after you’ve selected your water-sealing substance.

- Step 2: To guarantee that the water-resistant barrier is complete, any cracks will be patched with concrete.

- Step 3: To prime the structure’s exterior, apply a primary coat. These surfaces can be primed with water-based or solvent-based primers.

- Step 4: The walls are carefully cleaned so that the water-tightening solution bonds well with the concrete.

- Step 5: The walls are covered with a water-tightening layer.

- Step 6: Do finishing for the overlaps, edges, and angles to make sure that the bonding is proper.

The Final Word: Selecting the appropriate waterproof chemical and material for the particular application region becomes even more crucial to preserve the building’s strength, life, and functioning. Therefore, if the choice of material is poor, it could affect the whole building’s durability, strength, and usability. Check Out McCoy Mart to shop for the best quality products for your home.

Post A Comment