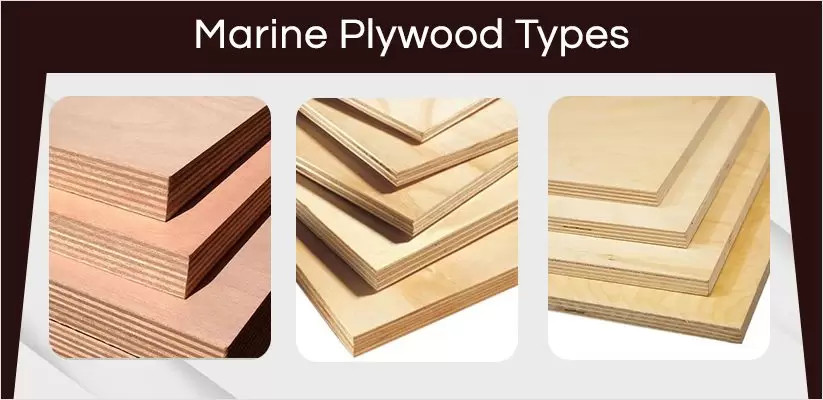

Solid wood has been historically used for manufacturing furniture, decorative items, and diverse other structures due to the durability standards the material offers in the long run. However, the introduction of plywood in the late 18th century revolutionized the industry with its incredible versatility, cost-effectiveness, and strength. Plywood, thin layers of wooden sheets bonded together, comes in a variety of types to cater to the different applications of the construction and manufacturing industry with remarkable specifications. Marine plywood, one of the essential types of plywood is known for its water resistance, versatility, longevity and strength, which has made it a great choice for diverse applications.

Post your Requirement

Suggested Post: What is Plywood? – Plywood Types and Its Uses

What is Marine Plywood?

Marine or waterproof plywood is a type of premium plywood that is designed to ensure the challenges posed by moisture-heavy environments. This is a specialized material made with the help of high-quality hardwood veneers that are bonded together with waterproof glue and a special treatment process to ensure effective resistance to moisture and the potential damage caused by exposure to water. The different layers of the hardwood veneers are arranged in a cross-grain pattern for added strength and dimensional stability of the structures.

They come with numerous impressive features like the ability to withstand diverse climatic conditions and resistance to rotting, warping, and delamination even in harsh conditions. Additionally, the boards of marine or waterproof plywood come in a variety of thicknesses and grades with each grade having its unique qualities and appearance. In a general sense, higher grades come with better appearance, qualities, and strength.

Exploring the Different Marine Plywood Grades To Make Informed Decisions

The standard plywood came into four main grades, A, B, C, and D with A usually being the highest grade. However, in the case of marine plywood, a dual grading system is followed. This typically means that both sides of the plywood sheet are graded separately to ensure better cost-effectiveness and features for the people. The essential marine plywood grades to be considered before choosing which one suits your needs best include the following:

1. A-A Grade

If you are someone seeking the highest grade or quality of marine plywood, an A-A Grade is the option for you. This grade is crafted with premium quality hardwood veneers that are typically characterized by features like uniform colour and grain patterns along with no existence of knots, defects, or voids. This is a kind of waterproof plywood that is made with the power of a waterproof adhesive and a cross-banding process where each layer is laid perpendicular to the previous one.

Key Marine Plywood Features For A-A Grade:

- Superior water-resistance.

- Excellent Durability.

- Incredible Stability.

- Smooth Finish and an Elegant Appearance.

Key Marine Plywood Uses for A-A Grade:

- Boat interiors, decks, and high-end joinery.

- Cabinets.

- Furniture and High-quality signage.

2. A-B Grade

This is one of the high-quality marine plywood grades that is ideal for diverse kinds of marine applications. Like the A-A Grade, A-B Grade is also manufactured with quality hardwood veneers that feature a uniform color and grain patterns to ensure superior strength and reliability to the users. However, this plywood grade features minor defects, such as voids or knots. They are also made with a waterproof adhesive and a cross-banding process to ensure effective moisture resistance and superior appearance and performance even in humid environments. This marine plywood grade might also have slight color variations but ensures consistent performance.

Key Marine Plywood Features for A-B Grade:

- High standards of stability.

- Incredible water resistance.

- Excellent strength and durability.

- Consistent Performance.

- Cost-Effective compared to A-A Grade.

Key Marine Plywood Uses for A-B Grade:

- Boat building and marine environments where one side will be visible.

- Flooring, paneling, and outdoor furniture.

- Other kinds of outdoor and marine applications.

3. B-B Grade

This is relatively a lower marine plywood grade that is particularly suitable for applications where strength and durability are a priority over the appearance of the structures. It is manufactured with hardwood veneers that may contain patches, knots, along other imperfections while remaining structurally sound and stable. They are also built with waterproof adhesive and come with commendable water resistance, stability, and durability in the long run.

Key Marine Plywood Features for B-B Grade:

- Excel at strength and durability.

- Minor imperfections but incredibly cost-effective.

- Reliable in the long run with waterproofing qualities.

Key Marine Plywood Uses For B-B Grade:

- Structural components of boats, flooring, and frames.

- Subflooring and underlayment.

- Industrial and construction projects.

- Other structural applications where appearance is not the foremost priority.

4. Medium-density Overlay (MDO)

This is one of the specialized marine plywood grades that serves to be a kind of variant featuring a resin-impregnated fibre layer on both sides, serving as a waterproof barrier. Similar to the A-A and A-B grades, the unique fibre layer of this grade is positioned in between two layers of hardwood veneers that are bonded with a waterproof adhesive in a cross-banding process. This grade features a uniform surfacer finish along with robust stability, durability, and water resistance making it perfect for diverse appearance-specific and strength-specific applications.

Key Marine Plywood Features for Medium-density Overlay Grade:

- Improved water resistance and resistance to weather, and abrasion.

- Decent durability.

- Smooth and paintable surface and thus impressive visual appeal.

- Solid stability compared to B-B grade marine plywood.

Key Marine Plywood Uses for Medium-density Overlay Grade:

- Signage and billboards.

- Outdoor furniture and cabinetry.

- Concrete formwork and construction projects.

5. High-density Overlay (HDO)

As the name suggests, the High-density overlay refers to a superior option of marine plywood grades that is typically characterized by a higher resin percentage that ensures the creation of a shinier, smoother, and harder surface. the grade offers incredible features like a uniform surface finish, superior water resistance along with enhanced water resistance and stability in the long run.

Key Marine Plywood Features For High-density Overlay Grade:

- Superior strength and moisture resistance.

- A smooth and durable surface.

- Solid stability compared to B-B grade marine plywood.

- High resistance to chemicals, abrasion, and weathering.

Key Marine Plywood Uses for High-density Overlay Grade:

- Boat exteriors, docks, and other relevant applications.

- High-end outdoor and marine furniture.

- Heavy-duty concrete forms.

- Industrial and commercial projects that need long-lasting surfaces.

|

Factors |

A-A Grade |

A-B Grade |

B-B Grade |

Medium-density Overlay (MDO) |

High-density Overlay (HDO) |

|

Quality |

Highest quality with a void-free core |

High quality with a generally void-free core |

Lower Quality and can have some core voids |

Lower quality than HDO but has a high-quality core |

Higher quality than MDO and B-B with a premium core |

|

Strength and Durability |

Maximum strength, and durability. |

High levels of strength and durability |

Structurally Sound |

Supports overlay durability with impressive strength |

High strength, ideal for heavy-duty use |

|

Appearance |

Smooth and free of defects. |

High quality on one side, minor defects on the other |

Moderate aesthetic appeal may have minor defects such as patches and knots. |

Smooth resin-treated surface |

Very smooth, high-quality resin-treated surface. |

|

Uniformity |

Uniform grain and colour pattern with no defect |

Uniform grain and colour pattern with minor defects |

Not uniform, contains defects, such as patches and knots |

Uniform surface finish |

Uniform surface finish |

|

Costs |

High |

Moderate |

Lower compared to A-A and A-B. |

Moderate to high, depending on resin quality. |

Highest among all grades due to superior durability. |

|

Applications |

High-end furniture, boats, cabinetry, and visible surfaces. |

Exterior furniture, and general construction. |

Subflooring, sheathing, or less visible structural uses. |

Concrete formwork, signs, and durable painted surfaces. |

Industrial use, concrete formwork, premium applications. |

Suggested Post: List Of Different Grades Of Plywood

Impressive Marine Plywood Features

There are numerous options in waterproof plywood such as BWP plywood, marine, and numerous others. Making an informed decision involves the determination of your specific needs and expectations from the material and the consideration of the specific features of the different options. Let’s dive deeper into the versatile features of marine plywood to understand better its suitability for diverse applications.

- Moisture Resistance: The term marine is related to the sea and thus the term marine plywood suggests that it is suitable for full submersion in water. This is accurate about the material as the marine plywood performs exceptionally well in environments that feature intermittent or prolonged exposure to moisture. The Marine plywood is made with an adhesive that is moisture resistant and the key feature of the plywood sheets is its resistance to moisture and the associated potential damage.

- Robust Strength: The marine plywood boards are made with premium-quality hardwood veneers that are bonded together with a waterproof adhesive to ensure superior standards of strength, sturdiness, stability, and durability to the structures. Marine plywood is ideal for diverse heavy-duty and complex applications due to its incredible performance and reliability.

- Impressive Durability: Marine plywood has built its reputation to offer high standards of durability even in the harshest of weather conditions. This is one of the most celebrated marine plywood features as its composition ensures it can withstand heavy loads, impacts, and other external forces. It is resistant to warping, corrosion, cracking, and splitting ensuring its longevity and reliability in diverse applications that require robust and resilient materials.

- Versatility in Uses: One of the key marine plywood features is that it is flexible to a wide range of design options and thus applications. The plywood boards can easily be cut, shaped, and formed to suit different project needs, additionally, the smooth surface finish allows for easy painting, staining, or varnishing, offering flexibility in achieving desired aesthetics. It is available in different grades and thicknesses to meet the specific needs of applications including boat building, furniture making, and construction projects.

- Cost-effective: While the upfront cost of marine plywood can be slightly more expensive as compared to the regular options, its remarkable features and qualities make it a smart investment in the long run. The long lifespan, strength, and resistance to moisture along with low maintenance and replacement needs ensure superior returns on investment thereby making the structures a worthwhile investment.

Cost of Marine / BWP Plywood in India

The cost of marine plywood sheets in India varies depending on a variety of factors such as the grades of plywood, the thickness, wood type, supplier, and certifications. For actual marine plywood prices, you can refer to the website or consult the local manufacturers. However, in a general sense, the price structures of different types of marine plywood can be defined as follows:

|

Thicknesses of Marine Plywood |

Marine Plywood Price Per Sq. Ft |

Marine Plywood Price Per Sheet |

|

4 mm |

₹30 – ₹50 |

₹1,000 and ₹1,200 |

|

6 mm |

₹35 – ₹60 |

₹1,200 and ₹1,500 |

|

9 mm |

₹40 – ₹70 |

₹1,400 and ₹1,800 |

|

12 mm |

₹50 – ₹80 |

₹2,000 and ₹2,300 |

|

16 mm |

₹70 – ₹100 |

₹2,500 and ₹2,800 |

|

19 mm |

₹80 – ₹120 |

₹3,000 and ₹3,500 |

|

25 mm |

₹120 – ₹160 |

₹4,000 and ₹5,000 |

Marine Plywood vs. Plywood

|

Factors |

Marine Plywood |

Plywood |

|

Definition |

A premium type of plywood designed to withstand moisture, humidity, and marine environment. |

A general-purpose wood panel used for a variety of interior and exterior applications. |

|

Moisture Resistance |

Highly resistant, and waterproof. |

Moderate resistance may swell. |

|

Applications |

Boats, docks, bathrooms, kitchens. |

Furniture, cabinets, general use. |

|

Construction |

Made with waterproof adhesive and high-quality veneers. |

Composed of multiple layers of wood veneers. |

|

Quality and Durability |

High-quality, durable, and long-lasting. |

Varies in quality, with lower grades offering less durability. |

|

Costs |

Relatively expensive. |

Generally more affordable. |

|

Plywood Grading Systems |

Meets stringent standards. |

Follows standard grading system. |

|

Longevity |

Can withstand harsh weather conditions. |

May deteriorate over time in unfavorable conditions. |

Read Also: Difference Between 303 and 710 Grade Plywood

Versatile Uses of Marine Plywood in India

As we have discussed before, the material of marine plywood is highly versatile and its void-free construction and water-resistant adhesive make it ideal for a wide variety of indoor and outdoor applications. Some of the common areas where marine plywood boards have found their use and applications are as follows:

- Boat Building: The marine plywood boards come with superior strength and resistance to moisture capabilities thereby making it ideal for use in the construction of boats and other watercraft structures. It is ideal for the building of hulls, decks, and interiors of boats due to its resistance to water damage and collisions.

- Docks And Piers: The durability and resistance to moisture damage of the different marine plywood grades also make it a preferred material for the construction of docks, piers, and other structures that are constantly exposed to water. They can also be used for the construction of lake platforms as they can withstand harsh environmental conditions with minimal maintenance and upkeep needs.

- Outdoor Furniture: The ability to withstand diverse climatic conditions also contributes to the suitability of the material in the manufacturing of different elements of outdoor furniture such as garden chairs, patio tables, benches, and whatnot. The properly sealed marine plywood boards ensure superior strength and long-term performance along with the beautiful aesthetic appeal of the smooth hardwood finishes. They ensure the longevity of the structures with an impressive appeal of luxury.

- Home Renovation: In environments where the humidity standards fluctuate all day such as kitchens or bathrooms, the options of waterproof plywood such as marine plywood prove to be excellent choices. Their resistance to moisture and water contact along with exceptional strength makes them ideal for the manufacturing of cabinets, flooring, paneling, and backsplashes in these spaces.

- Marine And Industrial Applications: The impressive marine plywood features make them ideal for specific kinds of marine and industrial applications as well. Marine plywood has made its place in diverse marine applications such as shipbuilding and others due to effective resistance to water damage. It can be effectively used in the manufacturing of industrial structures such as oil rigs, industrial storage units, and transport crates that encounter moisture or harsh environmental conditions.

Purchase High-Quality Marine Plywood For Effective Performance

Marine plywood serves as a cornerstone in the modern construction industry with its superior resistance to moisture and durability that make it the best choice for diverse applications. From bathroom furniture to boat building, marine plywood has made its irreplaceable place in diverse areas of the construction industry and ensures effective robustness and performance in each. It is often advised to the clients to have a brief understanding of the material, its different grades and features, and make an informed decision carefully considering the wide range of factors. This will help you get the best features and competitive prices for your plywood boards and thus build your structures with precision and quality.

Read Also: What Is Difference Between Plywood And Plyboard?

FAQ’s

Q:1 How is marine plywood different from other plywood options?

A:1 Marine plywood is a more advanced type of plywood that is designed specifically for high moisture and humid environments. It is manufactured with premium quality hardwood veneers with a waterproof adhesive and thus ensures higher resistance to moisture and rotting as compared to regular plywood options.

Q:2 Which marine plywood grade is best?

A:2 The A-A Marine plywood is the highest grade of plywood that comes with superior strength, durability, and water resistance making it suitable for a wide range of diverse applications in the industry.

Q:3 What are the benefits of marine plywood?

A:3 Marine plywood comes with exceptional water resistance, enhanced strength, durability, fungal resistance, and prevention of delamination which makes it a worthy investment. Additionally, its low maintenance and upkeep needs further add to the performance and longevity of the structures in the long run.

Post A Comment