Since the 1990s, the building industry has been changing in many ways. Despite the 2008 crisis and all the speculation that surrounded the growth, early 2000 saw a big boom in high rises and the market started looking up once again. Multi-story buildings, both commercial and residential, have been springing up across the country ever since. During the same time, technology in fabricating doors, windows and curtain walls also began evolving and along came the era of machining. The fabricators started to realize the significant role that machines play in fabrication and that it was actually possible to relieve a lot of headaches that comes along with the increase in demand.

Post your Requirement

Enquire Now for Doors

Gauging the enormous potential of the door window and façade fabrication industry, various international machine manufacturers started venturing into India to tap the unexplored waters. LGF Sysmac with machines from LGF, Italy was the 1st to recognize the possibility and emerged as a leading technology player. The late 90s, FOM, Italy entered the market, followed by Elumatec, Germany in 2005. Emmegi, Italy followed soon after in 2006. Subsequently several Turkish and Chinese companies entered the fray.

All the leading companies have their advantages and disadvantages and arguments over each other but it is interesting to see all of them have made a significant mark in India over last 2 decades. However, the real game-changer is the rise of CNC machinery market which even the suppliers themselves never imagined was possible in India. Much leading Aluminium curtain wall and window contractors have got CNC machines in their stable now. Some even started with CNC cutting machines and moved onto CNC profiles machining centers. Permasteelisa was the first company to start with CNC Profile Machining Center in India. 2005 – Alkarma and Star Alubuild in Delhi got their DALI 40 from FOM. A milestone in Bengaluru followed suit with the Elumatec SBZ 122. Emmegi sold a complete set up to Bhoruka Falcons in 2006. After a brief lull, the CNC market again picked up in 2008, with Duplex setting up the biggest Aluminium curtain walling factory in India in Gadwal with CNC machines. 2010-2013 saw many companies adopt CNC technology. Glasswall systems, Alufit, Geotrix, Alumayer, Green Façade, Hi-fab, Doors and Doors, SiddhivinayakInfrasystems, Alpro Industries are some companies that installed CNC machining Centers in their factories. Many went in for CNC Cutting Machines to automate their cutting operation. Today there are more than two dozen companies in India with CNC machining centers.

WHAT IS CNC Machines?

Computer Numerical Control (CNC) machines are automated milling devices that can manufacture industrial components without direct human assistance. They use coded instructions that are sent to an internal computer, which allows factories to fabricate parts accurately and quickly. There are many different types of CNC machines, ranging from drills to plasma cutters, so they can be used to make a wide variety of parts. The most common CNC machines are milling machines, lathes, and grinders. Milling machines automatically cut materials, including metal, using a cutting spindle, which can move to different positions and depths as directed by the computer instructions.

WHY CNC?

Advantages of CNC Machine

CNC Machines have the following advantages –

- CNC machines can be used continuously 24×7 throughout the year and only need to be switched off for occasional maintenance.

- CNC machines are programmed with a design that can then be manufactured hundreds or even thousands of times. Each manufactured product will be exactly the same.

- Less skilled/trained people can operate CNC machines unlike manual lathes/milling machines etc. which need skilled engineers.

- CNC machines can be updated by improving the software used to drive the machines

- Training for the correct use of CNC machines is available through the use of ‘virtual software’. This software is like a computer game that allows the operator to practice using the CNC machine on the screen of a computer.

- Modern design software allows the designer to simulate the manufacture of his/her idea. There is no need to make a prototype or a model. This saves time and money.

- One person can supervise many CNC machines as once they are programmed they can usually be left to work by themselves. Only the cutting tools need replacement occasionally.

CNC Machine Disadvantages

- CNC machines are more expensive than manually operated machines, although costs are slowly coming down.

- The CNC machine operator only needs basic training and skills, enough to supervise several machines. In years gone by, engineers needed years of training to operate center lathes, milling machines and other manually operated machines. This means many of the old skills are being lost.

- Fewer workers are required to operate CNC machines compared to manually operated machines. Investment in CNC machines can lead to unemployment.

- Many countries no longer teach pupils/students how to use manually operated lathes/milling machines etc… Pupils/students no longer develop the detailed skills required by engineers of the past. These include mathematical and engineering skills

DIFFERENT TYPES OF CNC MACHINING CENTERS –

For a layman to understand which type of machining center is available to choose from, we can say that there are primarily three types-

- 3 Axis – one can process a profile from TOP, FRONT and BACK – X, Y and Z axis

- 4 Axis – one can process a profile from TOP, FRONT, BACK and any angle from FRONT to BACK – X, Y, Z and A-axis

- 5 Axis means one can process a profile from TOP, FRONT, BACK, any angle from FRONT to BACK and LEFT to RIGHT – X, Y, Z, A, and C axis. In addition, a 5 Axis machine can do cutting, notching and process from the bottom of the profile too.

USAGE OF CNC IN FENESTRATION INDUSTRY-

Doors and Windows –

-

- The average height of Doors is 2.1m. In some cases, it may be 2.4m. In case of sliding doors, the width could go up to 4.5m. Windows are usually between 1.5m to 1.8m.

- A machine should be able to process a minimum of 1.5m and a maximum of 3.5m with a possibility to machine longer if required by rotation of the profile.

- Machining of lock slots, keyholes, locking points, and water drainage slots, can be done on both 3 Axis and 4 Axis machines.

Enquire Now for Sliding Doors

Facades –

- General Floor to Floor height is around 3.5m. In some cases, it could go up to 4.5m. The minimum processing length in the case of facades is 3.5m and to reduce loading and unloading time, a 2 station machine is advisable.

- Machining of holes for transom fixing, pressure equalization slots, notching at the bottom in case of unitized profiles.

POINTERS TO CHOOSE A CNC MACHINE

- Production Capacity

- Maximum processing length

- Processing Speed – Travel speed in X, Y and Z gives an indication of speed of processing.

- Spindle – Aluminium processing requires a minimum of 12,000 rpm. Higher speed offers better finish. Processing of thicker profiles may require high-power spindles.

- Shuttle/Oscillating operation – The machine is longer with 2 stations. The machine will process Station A and then move to Station B. The operator can change the profile in Station A. This will save time of loading and unloading. It is useful for Unitized facades. Station A can process Male Mullions. Station B can process Female Mullions.

- Compatibility with software / future connections to window production softwares

- Training and Service

Ten Tool Carousel and Automatic Tool Changer

For a better understanding of the above points WFM compiled basic but critical information about the 3 most popular and widely available 4 axis CNC machining centres for aluminium profile processing from 3 most aggressive Machine companies selling to Indian façade and Fenestration market – SBZ 140 from Elumatec, DALI 70 from FOM and Orion from LGF.

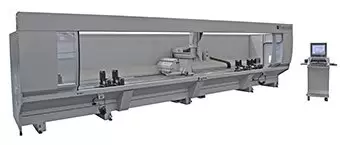

Elumatec – the world leader in machines for Aluminium and UPVC profiles took up this challenge to develop a 4 axis machine that could be fast, flexible, and do complex machining during the late 1990s and early 2000. It lead to the development of the SBZ 136, which evolved into the present-day SBZ 140 – the largest sold profile machining center from Elumatec worldwide. More than 700 machines are successfully running across the globe with window producers, curtain wall / façade producers and industrial profile processors. It’s double clamping per station enables processing of 2 unitized profiles at the same time. This is a big advantage for curtain wall producers.

Salient Features-

- It is one of the fastest in its class – 65 m/min in X axis, 60m/min in Y and Z.

- Faster spindle speed for smoother machining of Aluminium / UPVC profiles and power torque spindle for tapping applications or processing steel.

- Spindle and Electrical cabinet are equipped with cooling systems to keep the controllers and spindle under controlled temperature enabling continuous operation.

- Wider Y axis enables two profiles to be clamped on each station and X axis of 9.7m is useful for unitized curtain wall producers as in some cases the mullion lengths are more than 4m.

- Auto length measurement option to ensure dimensional accuracy with respect to end of profile.

- SBZ140 is bolted to floor after precise leveling to ensure repeatability, accuracy and level

Enquire Now for UPVC Profiles

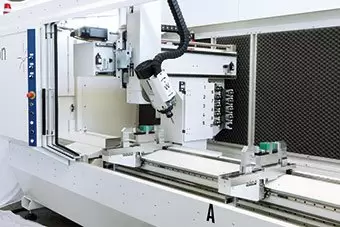

FOM INDUSTRIE have developed this CNC Machine keeping in view high production rate, consistency & qualitative performance, and mass production. The machine is designed keeping in mind the feedback received from major system companies across the world, and is equipped with right and proper technical specifications to handle all possible machining on Aluminium and uPvc profiles.

Salient Features-

- DALI 70 has two stations as a standard feature so this machine can be used to double its capacity while manufacturing window frames.

- User friendly softwares, FOM CAM and PRO F2, help in integration of machining center and Double Miter saw to handle any challenges in mass production.

- The structure consists of a machine bed with a beam that slides across the top of it. Both parts are made of steel and are duly stabilised after each work phase to ensure that there is no interior tension; they are of sufficient size to guarantee stability and precision during machining operations.

- The axes slide along high precision, robust and reliable linear guide-ways with recirculating ball blocks that have four points of contact equipped with oil scrapers and with medium/high preloading.

Enquire Now for frames

FOM INDUSTRIE not only offers its Clients a machine tool, but also a “turnkey” productive system to solve all of the problems involved in production. The company’s experience is at the client’s disposition to optimise the relationship between machining centre performance and the technological machining requirements. The service relies on:

- A CAD-CAM system for creating a project which provides for piece design, automatic creation of the program and simulation of the machining operations.

- A vast archive of projects created for companies operating in important industrial sectors (automotive, railways, naval, furniture, transport, aeronautic, textile).

LGF offers a product which is technically advanced and characterised by extreme robustness, with an optimal quality/price ratio, and also offers to customers excellent flexibility and a variety of products that easily meets any requirement. All their components findtheir the best expression in the highest degree of motivation and spirit of collaboration, always supporting the cause of LGF in the world. One of the factors that mostly contributed to the success of the company is their continuous, precise, effective, and timely after sale assistance service both in terms of technical support to the clients and in terms of spare parts supply.

Salient Features-

- Orion comes in a bed length of 4 mtrs., 7 mtrs. and 10 mtrs.

- Possibility of a completely enclosed version that permits enhanced safety and is less noisy in operation.

- A version with only safety perimeter fence is also available.

- It can process profiles of lengths upto 9800 mm

- The maximum width of job processed is 1000 mm

- The maximum depth of job processed is 500 mm

- Orion has an Automatic Tool Changer with a 10-tool carousel.

- It can do end milling operations, apart from all drilling and milling operations.

- The Orion can process jobs on two separate stations along its length. Thus, when the processing is going on in one station, the Loading and Un-Loading can proceed in the other station. This reduces/eliminates unproductive loading and unloading time, thereby increasing productivity.

- Jobs longer than the bed length can also be processed on the machine.

- Two profiles can be processed together side by side by the use of special clamping systems.

- Special clamping systems are also available for processing Panels, clamped vertically.

COMPARATIVE ANALYSIS

| Descriptions | SBZ140/9.7M | DALI 70 | LGF Orion/ 7M |

|---|---|---|---|

| Travelling distance X axis | 9700mm @ 65m/min | 7320 mm,Vmax 100m/min | 7000mm @ 70m/min |

| Travelling distance Y axis | 850mm @ 60m/min | 1050 mm,Vmax 33m/min | 1000mm @ 50m/min |

| Travelling distance Z axis | 650mm @ 60m/min | 435 mm,Vmax 13m/min | 500mm @ 30m/min |

| Rotational Axis towards Y (4th axis) | +/- 90 Deg | -15 / 195 deg | |

| Max. processing length w/o processing the ends | 9700mm | 7000mm | 6980 mm |

| Max. processing length with processing the ends | 9580mm | – | 6940 mm |

| Working capacity: | |||

| Top side of profile | 645(w) X 250 (h) mm | 220(w) x 220(h) mm | 225 (W) x 200 (H) mm |

| Top & front side of profile | 450 (w) X 250 (h) mm | 200(W) x 200 (H) mm | 225 (W) x 200 (H) mm |

| Top, Front , Back side of profile | 300 (w) X 250 (h) mm | 200(W) x 200 (H) mm | 225 (W) x 200 (H) mm |

| Double clamping + angle head | 80 (w) X 250 (h) mm | Not Available | Available |

| Comparison Chart | |||

| Positioning accuracy | +/- 0.1mm | +/- 0.13 | +/-0.2mm |

| Spindle speed | 24000rpm | 12000rpm | Upto 18000rpm |

| Power output at spindle | 10Kw,S1(Power – Torque) | 4Kw (5.3 HP) Type- S1 | 5.5Kw |

| Tool Chuck | HSK-F63F | ISO30 | ISO30 |

| Tool storage capacity | 8 tools+ 1 angle head | Standard 7 tools, Optional 3 tools | 10 tools |

| Cutter diameter | 80max. | 50mm | Not Mentioned |

| Disk cutter diameter | 200mm max. | 115mm | 100 mm |

| Compressed air supply | >7bar | >7bar | >7bar |

| Air consumption per cycle | 180lpm | 90 NL/C | 100 litres |

| Power supply | 400V,3 phase,50Hz,35A | 400V,3 phase,50Hz | 400V,3 phase,50Hz,43A |

| Total length | 13440mm | 8675 mm | 8900 mm |

| Width | 3430mm | 2051 mm | 1700 mm |

| Height | 2950mm | 2341 mm | 2350 mm |

| Weight | 5900Kg | 4200 Kg | 3775 kg |

| Standarad items included in basic price | SBZ140/9.7M | DALI 70 | LGF Orion/ 7M |

| Windows Xp platform | Yes | Yes | Not mentioned |

| Automatic tool changer | Yes | Yes | Yes |

| Horizontal pneumatic material clamps | 12nos.(6 each station) | 6 nos. standard | 4 nos standard. Extra on demand |

| Automatic clamp recognition | Yes | inclusive | Yes |

| Automatic clamp movement | Yes | Yes | Yes |

| Swinging Operation Option between Stations | Yes | Yes | Yes |

| Multi-piece Option | NO | Yes | Yes |

| Dynamic Swing Option | NO | Yes | Yes |

| Safety | Light Barrier and fence | Complete colsed cover while working | Completely Enclosed Construction |

| Construction | 3 pieces joined and bolted to floor | Electro Welded Solid Steel |

We have offers of these Door Hardware (Door Closer, Door Handle, Door Hinges, Door Locks, Cylindrical Lock, Mortise Locks) with high discount. You can choose multiple types of door hardware from top brands.

Post A Comment