Ceramics Material Used In Modern Times

The ceramic industry has seen a massive shift over thousands of years. It contributed to the advancement of technology, electronics, medical equipment, transportation, and other fields. It may now be learned for aesthetic or utilitarian purposes. Its products are all around us in our daily lives. Their tiles can be used to embellish the floors, walls, and kitchen counters of one or more rooms. Roof tiles made from this material are frequently used to insulate structures, form a water barrier, and allow adequate water drainage.

Post your Requirement

The tiles of the space shuttle are one of the most spectacular applications of ceramics in the contemporary world. They are presently employed in computers, electrical systems, and other devices. Scientists are still experimenting with this substance and they have found that it is a diverse material that can be used to develop newer, stronger, and more versatile products. This product has drastically altered the world we live in today.

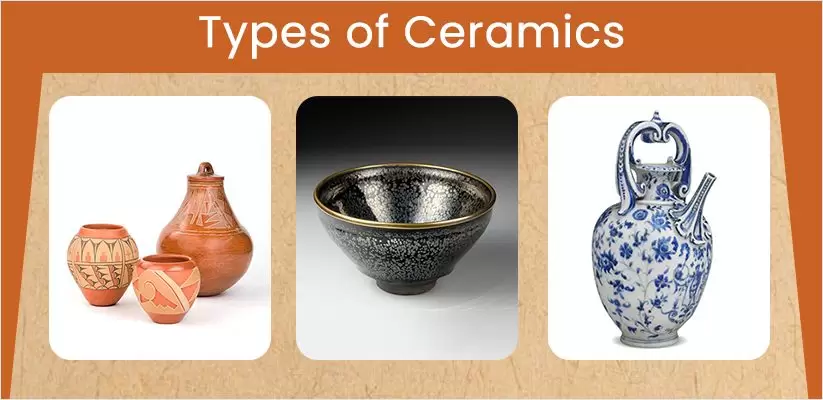

Types Of Ceramics

It is an inorganic non-metallic solid that has been moulded and then solidified by heating to high temperatures. They are tough, corrosion-resistant, and fragile in general. Nowadays, the term “ceramic” encompasses a broader range of materials, including glass, silicon, and some other concrete systems. Here are two broad categories in which it is divided:

-

Advance ceramics

-

Traditional ceramics

-

Advanced Ceramics

Technical, special, and high-performance ceramics are all terms used to describe this product. They are designed to endure harsh environments and applications. They are, for example, very resistant to temperature, melting, wear, corrosion, and other factors. It is an inorganic, non-metallic, mostly crystalline product with a well-regulated composition (grain size and shape, phase distributions, and porosity) that is made with precision from highly refined and characterised raw materials with exactly defined properties.

-

Traditional Ceramics

Traditional ceramics are antique clay that is often made from naturally existing raw materials such as clay, quartz, and feldspar. The phrase “traditional ceramics” is frequently used to describe a clay composition of more than 20%. Earthenware, stoneware, porcelain, and bone china are common examples. One of the most readily available raw materials for making different clay products. Different types of clay and clay mixtures with various silica and other mineral changes result in various forms of pottery.

Understand Traditional Ceramics and their Different Types

These are made of clay. Earthenware, stoneware, porcelain, and many other types of pottery are represented here. The nature of the end product is determined by the composition of the clays used, the type of additives used, and the firing temperatures. Have a look at is types to know more about them:

Types of Traditional Ceramics

Earthenware:

It is pottery clay that has not been vitrified (the process by which crystalline silicate components join to form non-crystalline glass compounds). This increases the porousness and coarseness of the pottery. Until the 18th century, earthenware pottery was the most prevalent form. Terracotta, unglazed clay-based pottery, is a typical form of earthenware. Planters constructed of terracotta, as well as bricks, water pipes, and other materials, are prevalent nowadays.

Stoneware:

It is a vitreous or semi-vitreous product that is enamelled to give it a glassy appearance and make it nonporous. In comparison to other substances, stoneware is fired at high temperatures. Because of imperfections in the clay, it usually has an earthy tone. This clay is heated at a high temperature (approximately 1,200°C) until it resembles glass (vitrified). Because stoneware is non-porous, the glaze is utilised on it for decorative purposes. It’s durable, chip-resistant, and long-lasting which makes it ideal for cooking, baking, storage, and serving dishes in the kitchen.

Porcelain:

These are manufactured by heating substances, usually kaolin clay, to temperatures ranging from 2,200 to 2,600 degrees Fahrenheit in a kiln. In comparison to other forms, porcelain is a relatively heat-resistant and sturdy substance. This is due to the vitrification process and the creation of mullite, a silicate mineral when heated. Bathroom and kitchen tiles, containers, ornamental sculptures, and other porcelain are common.

Bone China:

Bone china, commonly known as fine china, is translucent porcelain with a high strength and chip resistance. It was created by an English man -Josiah Spode circa 1800 and consists of a mixture of bone ash, feldspathic, and kaolin. Bone china may be sculpted into narrower shapes than porcelain since it is very robust. Because of the different mineral characteristics, it is transparent.

Advanced Ceramics and Their Different Types

They refer to all products created through a series of specialised manufacturing processes from inorganic, high-purity compounds. Because of their conductivity, magnetism, insulation, and heat transfer, they can be used for a variety of applications. They rely on oxides, non-oxides, or a combination of the two. Read on to know more about its many types:

Types of Advanced Ceramics

- Aluminium nitride: The thermal conductivity of Aluminium Nitride (AIN) is excellent. Excellent thermal shock resistance and corrosion resistance are further features. It is used in many electronic applications, such as high-frequency electrical circuits, because of its typical properties, which include good electrical insulation but high thermal conductivity. AlN is employed in power electronics, aerospace systems, railroads, optoelectronics, semiconductor processing, microwave, and military applications because of these qualities. Heaters, windows, IC packages, and heat sinks are examples of common uses.

- Diamond (C): It is the most difficult substance known to exist in nature. It has a variety of uses, including industrial abrasives, cutting tools, and abrasion-resistant coatings. Of course, it’s also used in jewellery.

- Lead zirconium titanate (PZT): When electrical impulses are supplied to a piezoelectric material, it vibrates and translates vibration into electrical signals. It is the most frequently used piezoelectric, and it is utilised in gas igniters, ultrasonic imaging, and underwater detectors.

- Silica (SiO2): It is the most extensively used substance since it is a key component of many engineering. Thermal insulation, abrasives, laboratory glassware, and other applications employ silica-based products. It was also used in the communications industry as a component of optical fibres. Silica is used in tires, paints, and other products.

- Silicon carbide (SiC): When silicon carbide grains are bonded together in a process called sintering, a very hard product is formed. It is utilised in applications that need great endurance, including vehicle brakes, automotive clutches, and bulletproof vests, due to its hardness. Silicon carbide is the semiconductor most suited for power applications due to its ability to endure high voltage.

- Titanium oxide (TiO2): It is usually found in paints as a pigment. It’s also found in several glass ceramics. It is used to make other products such as BaTiO3. They have been widely used as an important force, heat, electricity, and light-sensitive functional material in sensors, ultrasonic transducers, microdisplacement devices, and other electronic components, among other applications.

- Titanium boride (TiB2): It has excellent hardness qualities and hence finds use in the manufacture of armour. For use in hot-pressed composite materials, they have excellent electrical conductivity like Evaporation boats for continuous aluminium metallization, crucible material for non-ferrous metals, aluminium shell moulds, and hot-pressed armour plates.

- Uranium oxide (UO2): This oxide of uranium is a black, radioactive, crystalline powder that naturally occurs in the mineral uraninite. It’s used in nuclear reactors’ nuclear fuel rods. Because its crystal structure can accommodate the fission products, it possesses outstanding dimensional stability.

- Yttrium aluminium garnet (YAG, Y3Al5O12): Its primary application is in lasers (Nd-YAG lasers). It’s also widely used in military, medical, and meteorological applications. It works well at room temperature, has a high slope efficiency, and operates at a wavelength with a relatively low risk of eye damage.

- Zirconia (ZrO2): Among other types, zirconia is the strongest and hardest substance. It’s used to make unique blades for high-performance scissors and knives, which was formerly thought to be impossible. Due to its high refractive index, which generates a diamond-like brilliance, single-crystal zirconia is also employed in ornamental applications and jewellery.

Check Out Different Types of Ceramic from McCoy Mart

McCoy Mart is the place to go if you need to purchase high-quality hardware, construction, and home improvement components among other things. The website offers authentic products at very reasonable prices. If you subscribe to a Pro account, you can customise the search results by changing the browser and app settings.

Post A Comment