Plywood is a kind of engineered wood that has found its use in a wide variety of applications, ranging from as basic as the manufacturing of furniture to the building of diverse large structures in the construction industry. If you look around yourself, you will find yourself surrounded by different kinds of structures made with different kinds of plywood. Plywood is a kind of wood material that is made by stacking several thin layers of wood veneers. The economical and durable plywood boards are machine-made and do not warp or crack thereby making the structures a reliable option for a versatile range of applications.

Post your Requirement

What is Plywood?

The widely used engineered wood is manufactured by gluing together several layers or plies of thin sheets of wood veneer. These wooden chips are glued together with an adhesive to create a thicker panel that offers superior standards of durability, reliability, and performance in a wide range of applications. The different plies are oriented in a way that the direction of the grain in one of the plies is rotated at an angle of 90 degrees to its adjacent plies. The use of cross-graining techniques ensures that the structures offer high levels of strength, stability, and resistance to shrinking, cracking, and warping capabilities.

How is Plywood Made?

The first and foremost component of manufacturing high-quality plywood is sourcing high-quality timber. If you want superior qualities and properties in the final structures, you first need to source high-quality material. Once the material is finalized, it is peeled into thin sheets that are called veneers. These thin sheets are the structures that are used for the manufacturing of quality plywood.

The veneers are then dried to remove any moisture if left and then laid in alternating directions to create a cross-grain pattern that ensures the resistance of the structures against expanding, contracting, and warping. At last, a strong adhesive is used to glue the thin sheets together and the panels are pressed under high pressure and heat to make the structure hard and stable.

Here your plywood is almost ready, you just need to cut the large board into panels of different sizes and finishes based on your application needs and requirements.

Suggested Post: How To Choose The Right Plywood For Your Project?

Widely Used Plywood Grades in India

The different types of plywood are graded based on the quality of the veneers that are used for the manufacturing and the overall look of the structures. It is quite crucial to choose the right grade of plywood for your specific application as it plays an influential role in the success and durability of your project. Some of the common grades of plywood include the following:

1. A Grade Plywood

One of the most widely used plywood grades for building smooth surfaces, this is the highest quality material that comes with smooth, blemish-free finishes. This is one of the best choices for applications where appearance is a priority, you can craft different kinds of decorative wall panels, cabinets, or other furniture elements, A grade plywood can be used for its smooth surface and a guaranteed flawlessness that helps in the creation of a refined and attractive look.

Key Uses Of A Grade Plywood:

- Wall paneling.

- Cabinetry and other shelving needs.

- Decorative accents.

- High-end furniture.

2. B-Grade Plywood

This is the second grade of plywood that comes with several minor imperfections and knots making the structures suitable for applications where appearance is not the priority. Mainly used for functional designs, this is a smooth material that comprises tiny and usually filled-in defects that ensure a near-perfect surface ideal for diverse applications. You can use this balance of form and function for the building of structures like bookshelves, countertops, interior panels, and other similar structures.

Key Uses Of B Grade Plywood:

- Interior Panels.

- Shelving applications.

- Furniture that needs a dust-free finish.

- Decorative elements need a fine surface.

3. C-Grade Plywood

This is the go-to option for you if strength is your priority and preference over appearance or smooth finishes. This is one of the popularly used plywood grades where the structures are featured with larger knots, blemishes, voids, and imperfections that are often visible making the structure a not-so-attractive one. However, the higher levels of strength and durability make the material a great option for structural components such as subflooring, framing, and others.

Key Uses Of C Grade Plywood:

- Subflooring.

- Framing.

- Roof sheathing.

- Hidden structural support.

4. D-Grade Plywood

This is the lowest one among the plywood grades in India and thus is neither very aesthetically appealing nor very strong and stable. This structure often features a lot of knots and voids on the surface and thus is mainly used for non-structural applications such as sheathing or backing for other materials.

Key Uses Of D Grade Plywood:

- Under-flooring.

- Temporary structures.

- Underpinning.

Read Also: List Of Different Grades Of Plywood

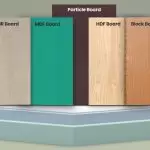

Popular Plywood Types in India

Different plywood types are widely used for a diverse range of applications in the construction and manufacturing industries. Therefore, if you are heading out to buy a plywood board, you might get overwhelmed with the range of options you have in the market. Therefore you need to have a brief understanding of the different types of plywood, their key features, and qualities to choose the right plywood type for you.

1. Softwood Plywood

One of the most widely used kinds of plywood sheets in India, softwood is made from one of the softwood species like cedar, fir, or pine. This wood is mainly available in large sheets and has become a preferred choice in the industry due to its lightweight nature and affordable pricing structure. This is an easily accessible material that is often used for applications such as construction, furniture, cabinets, and packaging purposes. The financial availability and versatility of the material make it a great choice for diverse applications.

The Key Advantages Of Using Softwood Plywood

- Used for structural purposes such as flooring, wall panels, and roof sheathing.

- Good strength for general construction.

- Easy to handle and work with.

2. Hardwood Plywood

Typically made with hardwood species like oak, birch, or maple, Hardwood is a superior plywood type that offers an impressive standard of strength, and resistance to warping. With its incredible visual appeal and the ability to be customized to diverse options, it finds its use in the manufacturing of high-finish cabinetry, furniture, carpeting, and ornamental paneling.

Key Advantages Of Using Hardwood Plywood:

- Ideal for furniture, cabinetry, and decorative applications.

- Resistant to wear and tear.

- Superior standards for strength and durability.

- Excellent for aesthetic purposes and long-lasting furniture.

3. Structural Plywood

Specially designed for load-bearing heavy installations, structural plywood is a kind of plywood that is made with the power of strong adhesives and premium veneers to ensure a high standard of stability and strength. This kind of plywood is used for heavy-load applications such as roofing, flooring, formwork, and bracing in construction projects.

Key Advantages Of The Structural Plywood:

- Ideal for heavy-duty applications.

- Cost-effective and moisture-resistance

- Sustainable and lost-lasting option

4. Marine Plywood(BWP Plywood)

As the name suggests, Boiling Water Proof Plywood(BWP Plywood) is a kind of plywood that is designed for usage in moist or humid regions. This is a kind of building material that is made with the power of waterproof adhesives and strong wood species to ensure effective resistance to water damage and thus superior performance in diverse climates and conditions. With its durable nature, marine plywood finds influential applications in purposes like building boats, docks, and fittings for the bathroom, kitchen, and other spaces that are exposed to moisture.

Key Advantages Of The Marine Plywood:

- Perfect for boat building, docks, and other outdoor applications.

- Excellent durability and longevity in wet conditions.

- Resists decay, fungi, and other corroding elements.

5. Commercial Plywood(BWR Plywood)

BWR(Boiling Water Resistant) is a kind of plywood, meticulously made with lower-cost species of wood to ensure effective application in spaces where creating a clean and polished surface is the foremost priority of the people. Commercial plywood ideal for purposes where strength and durability are not a priority as these structures are not particularly resistant to dampness or exposure to moisture. Therefore it is often the best choice for wardrobes and cabinets or other dry areas such as bedrooms, living rooms, and others.

Key Advantages Of The Commercial Plywood:

- Lightweight products with an affordable price tag.

- Superior aesthetic appeal and wider options for customization.

- Wide availability to meet specific and diverse needs of the people.

Suggested Post: What are Commercial Plywood – It’s Types and Sizes

6. Tropical Plywood

This is a kind of plywood made with the material of durable hardwood species from tropical regions such as meranti, luan, and keruing. These strictures are made precisely to ensure superior consistency in strength and appearance and are also effectively resistant to moisture and temperature fluctuations. This ensures a sustainable approach where high-quality materials are used for the creation of reliable structures.

Key Advantages Of Using The Tropical Plywood:

- It is a versatile and durable product for diverse applications.

- This wood material offers effective resistance to moisture and performs well in humid, tropical climates.

- It is aesthetically pleasing and thus can be used for various applications.

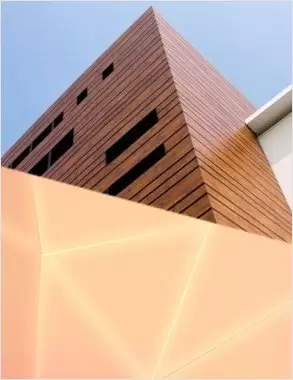

7. Exterior Plywood

As the name suggests, this is a kind of plywood that is mainly designed for outdoor applications where higher standards of durability, moisture resistance, and performance are an essential need. They have a tough and strong nature and are made with a water-resistant adhesive in construction thereby offering long-term reliability for a versatile range of outdoor applications.

Key Advantages Of Exterior Plywood:

- Used for siding, roofing, and general exterior projects.

- Cost-effective for outdoor construction.

- Withstands occasional exposure to moisture.

8. Interior Plywood

Mainly designed for diverse applications in regulated and dry environments, this is a kind of plywood made with softwood or hardwood to offer superior levels of appearance and functionality. This perfect balance of form and function with a smooth surface is used for diverse applications in the manufacture of furniture, shelves, cabinets, and wall paneling elements.

Key Advantages Of Interior Plywood:

- Suitable for indoor applications like furniture, cabinetry, and paneling.

- Easy to work with and can be painted or easily stained.

- Affordable and flexible for various woodworking projects.

Price Structure Of Different Types Of Plywood

|

Plywood Types in India |

Plywood Price |

| Softwood Plywood | ₹25 – ₹70 per sq ft |

| Hardwood Plywood | ₹20 – ₹150 per sq ft |

| Marine Plywood | ₹55 – ₹160 per sq ft |

| Commercial Plywood | ₹30 – ₹100 per sq ft |

| Tropical Plywood | ₹25 – ₹170 per sq ft |

| Exterior Plywood | ₹38 – ₹110 per sq ft |

| Interior Plywood | ₹30 – ₹120 per sq ft |

Common Uses Of Plywood in Diverse Industries

Plywood is one of the integral components of a wide variety of industries due to its impressive properties and reliability for a wide range of applications. Some of the essential uses of plywood include the following:

- Construction And Structural Support: Plywood is a material that offers an incredible ability to provide robust structural support and stability to different kinds of construction projects and structures. The strength, the resistance to warping and the superior agility to withstand heavy loads with ease make the different plywood types a great choice for the creation of solid foundations for buildings, and for different sheathing, roofing, and flooring applications in construction projects.

- Manufacturing Furniture: Plywood boards are some of the most celebrated elements in the furniture industry due to the versatility of applications they offer excellence and precision. whether it be cabinets, tables, chairs, wardrobes, or other elements, the strength, durability, performance, and aesthetic appeal of the plywood in the long run make the structures the best choice.

- Interior Design Elements: The flexibility of the sheets in different industries makes them an integral component of the interior design industry as well. Customized and stylish options for plywood are used for the manufacturing of unique elements such as wall paneling, room dividers, shelving, decorative elements, and numerous others. Interior designers prefer plywood for the long-term performance and beauty they offer with these elements.

- Boat Building: The resistance to moisture, water, and humid conditions and the associated damage in plywood make it a great option for the building of boats and other relevant structures. They have a lightweight nature, offer long-term durability, are strong and sturdy, and prove to be versatile choices for the constriction of hulls, decks, and other vital components of the boats or ships thereby contributing to the overall integrity and safety of the structures.

- Automotive Industry: The flexibility and resilience of the plywood boards make the structures a valuable resource in the automotive industry as well. These structures are widely used for the building of templates, molds, or other interior components of the vehicles such as dashboards, instrument boards, etc. It helps to enhance the aesthetic appeal of the vehicles, makes them more lavish and rich, and is used for the manufacturing of its prototypes and other design elements.

- Packaging Industry: Plywood serves as a staple in the packaging industry with its wide use in the creation of boxes and crates that are used to ship all kinds of products. They offer enhanced strength and durability to these boxes and ensure their safe transportation with improved protection. They do not add to the weight of the structures and yet offer long-term reliability making them a go-to choice almost for everything.

- Displays And Signage: The different types of plywood are usually designed to have a smooth surface that can hold paint and give an eye-catching level of aesthetic appeal to the user. Therefore the material of plywood offers a durable and visually appealing canvas to people that can be used to meet specific needs of people and can be tailored to create your kind of shop signs, exhibition displays, marketing boards, or other promotional materials.

- Cabinetry And Joinery: The stability, resistance to moisture, corrosion, and warping of the wood materials of plywood make it a perfect choice for the manufacturing of different types of cabinets and shelves whether for the kitchen, bathroom, or any other space. They help in the creation of long-lasting storage solutions that can stand the test of time with their reliable structures and beautiful looks.

Shop The Highest Quality Plywood For Building Sturdy Structures

Plywood, as we have discussed above, is a versatile and durable material that plays an integral role in a wide range of industries with its remarkability in impressing clients. From construction to the furniture industry, boat building to automotive, cabinetry to wardrobes, and a plethora of other industries, the unique combination of strength, flexibility, and cost-effectiveness in plywood makes it the ruling element for almost everything. However, to ensure the benefits and superior properties, you first need to get the highest quality right type, and grade of plywood. You should do proper research and then browse through the hundred options to find what works best for you.

Read Also: Top 10 Plywood Companies in India

Post A Comment