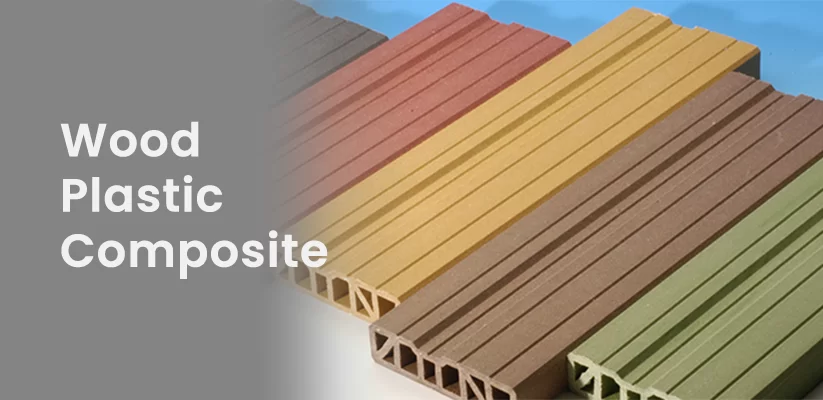

Starting a construction project is a comprehensive task that requires strategic decision-making about a wide range of materials, processes, and stages. If you have invested yourself in one, you must know the challenges that come while you explore the different kinds of materials used in the construction of diverse structures. While wood and the advanced innovations of materials such as plywood, MDF boards, and others have been historically used for the manufacturing of diverse elements of homes or offices, there has been recent popularity of one of the most unique options, the WPC or the wood composite plastic. Wood composite plastic refers to a material that combines wood fibres with thermoplastics, thereby eliminating their shortcomings and offering the advantages of both.

Post your Requirement

What is WPC?

Before we dive deeper into the meaning and applications of the material of WPC, let’s understand the WPC Full form. WPC stands for Wood composite plastic, which means a combination of wood and plastic. This is what the material means in the most basic sense.

The material Wood Plastic Composite (WPC) typically refers to a kind of engineered material that is typically made with the combination of wood fibres or sawdust with thermoplastic resins such as polyethene, polypropylene, or polyvinyl chloride (PVC).

The material has been constantly evolving to meet the changing needs of the construction industry with the durability of the plastic and the aesthetic appeal of the wood. The final product of this material comes with superior longevity with features like weather resistance properties and low upkeep needs in the long run. The material of WPC is manufactured under an extrusion process where the wood and thermoplastics are first mixed and then heated to create a uniform structure with quality and consistency.

Specifications of WPC

|

Factors |

Common Specifications |

|

Thickness |

2 mm to 25 mm |

|

Density |

600 kg/m³ to 800 kg/m³ |

|

Colour |

Natural brown to artificial colours |

|

Texture |

Smooth to rough |

|

Additives |

Fillers, stabilizers, antibacterial agents, UV inhibitors, etc. |

What Are The Common WPC Types in India?

The material WPC (wood composite plastic) serves to be a hybrid material that is made with a meticulous combination of wood fibres and plastic to feature the benefits of both materials in diverse construction applications. There are numerous WPC types that are widely used in applications such as cladding, furniture, decking, doors, and other structures. Some of the common types of WPC materials based on their composition include the following:

1. PE WPC (Polyethylene-based WPC)

This is a kind of material that is primarily made with a combination of polyethylene (PE) and wood fibres. This innovative choice comes with features like incredible flexibility and adaptability to different applications and is an accessible choice for diverse outdoor uses.

Key Properties of the material:

- Most common and cost-effective WPC type.

- Good flexibility and impact resistance.

- Moderate moisture resistance but less durable than PVC WPC.

- Particularly used for applications such as fences, decking, garden and benches, and other types of outdoor furniture elements.

2. PP WPC (Polypropylene-based WPC)

This is a type of material that is made with a meticulously manufactured process that includes the primary raw materials of polypropylene (PP) and wood fibres. This material is known for its enhanced levels of strength and effective resistance to heat making it perfect for diverse structural applications.

Key Properties of the Material:

- Stronger and more rigid than PE WPC.

- Higher heat resistance, making it suitable for high-temperature environments.

- Better mechanical properties, used in structural applications.

- Mainly used in the manufacturing of industrial pallets, interiors of automotive vehicles, and even different elements of office furniture.

3. PVC WPC (Polyvinyl Chloride-based WPC)

This is one of the most widely used and versatile WPC types in India. Made primarily with the materials of polyvinyl chloride (PVC) and wood fibres, this type of material is designed with incredible durability, low maintenance needs, and tempting performance in mind.

Key Properties of the material:

- High durability and water resistance (almost waterproof).

- Termite-proof and rot-resistant.

- Fire-retardant, making it safer for indoor applications.

- Higher density compared to PE and PP WPC.

- This is one of the most widely used materials known for its role in the manufacture of high-quality doors, windows, bathroom partitions, wall cladding solutions, and numerous others.

4. PLA WPC (Polylactic Acid-based WPC)

This is one of the newest innovations in the industry that is gaining popularity due to the rising consciousness among people for the conservation of the environment. This is a kind of WPC material that is composed of wood fibers and biodegradable Polylactic Acid (PLA) that ensures the creation of strong materials that are eco-friendly as well.

Key Properties of the material:

- Eco-friendly and biodegradable.

- Comparable strength to PP WPC but with a sustainable composition.

- Less common in commercial markets due to higher costs.

- This type of material is mainly used for eco-friendly packaging purposes, sustainable interior panels, disposable cutlery options, and other materials.

Essential WPC Benefits to Consider

The WPC proves to be an excellent alternative to traditional wood or the different types of plywood with its superior strength, durability, and performance in the long run. The different types of WPC boards are typically manufactured with the extrusion or compression process that creates a meticulous mixture of wood fibers or flours along with thermoplastics into thin WPC sheets. One of the key features of thermoplastics is that they can be melted and reshaped multiple times without losing their properties thereby ensuring flexibility in applications with remarkable benefits. Other than the versatility, there are a plethora of other WPC benefits, some of which are as follows:

- Durability and Strength: One of the most significant benefits of using the material for WPC in your construction projects is that they come with impressive durability and sturdiness. The material is designed to withstand elements such as rain, humidity, chemicals, and diverse other environmental conditions which makes the material a reliable choice. Additionally, the WPC boards or sheets are incredibly easy to use and fix. They also offer effective resistance to warping, cracking, corrosion, or splintering further contributing to its durability.

- Eco-Friendly and Sustainable: The WPC boards prove to be an environmentally friendly alternative as compared to other potential choices. The material is biodegradable and can also be 100 % recyclable with the use of materials such as wood, plastic waste, or agricultural waste in manufacturing. It also contributes to the conservation of natural wood resources thereby contributing to both a better environment and reduced global waste generation.

- Low Maintenance: One of the key features that make the WPC boards a better choice over wood and other relevant materials is its low maintenance needs. With the power of Plastic, the material does not require regular sealing, painting, or staining and can be easily maintained with regular repair or replacement. The WPC doors, windows, and other structures are also significantly easy to maintain with simple cleaning, stylish look, and low maintenance needs.

- Weather Resistance: WPC is a meticulously designed material that is built to withstand extreme weather conditions and still offers a performance that wows everyone. Whether it is about intense sunlight, UV rays, or heavy rains, the material is designed to ensure excellence in each. It is made with effective resistance to UV rays, and moisture that helps to prevent the concerns of fading cracking, and degradation over time. This also makes the material suitable for kitchen or bathroom cabinets as it is consistently exposed to moisture.

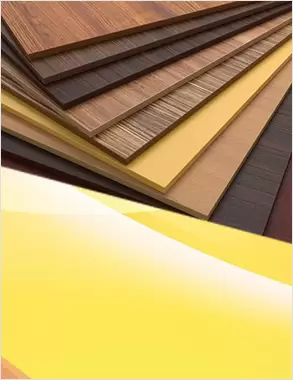

- Aesthetic Appeal: The material of WPC keeps up with the changing trends in the industry and thus offers the client the benefit of customization. The material is available in a variety of colors, textures, and even finishes to mimic the look of wood and other materials. Additionally, the material can be easily molded into diverse shapes and sizes with the help of CNC routers or laser cutters, can be used in combination with other materials such as glass or ACM boards for unique designs and create a stylish look for unique interior and exterior uses.

- Termite Resistance: This is one of the most tempting qualities of the material. The WPC boards are designed with effective resistance to termites, insects, and fungi and thus to rotting. The material is designed to withstand outdoor conditions without deteriorating, warping, and decaying making them a great choice over wood for outdoor uses.

- Fire Resistance: The WPC boards or sheets have become one of the most widely used materials in the construction industry not just with strength and durability but also with premium features like resistance to diverse conditions. The material also comes with superior resistance to fire than natural wood. The material does not support combustion easily and also does not promote the emission of toxic gases or smoke harmful in case of fire.

- Easy Installation and Versatility: The WPC is a lightweight material that comes with impressive strength and sturdiness making it a versatile choice for different applications. Additionally, it is designed to be cut, drilled, or shaped easily thereby making it a suitable material for quick and efficient installation in diverse uses.

|

Pros |

Cons |

|

Durability: Resistant to rot, decay, and insect attacks. |

Higher Initial Cost: More expensive than natural wood upfront. |

|

Low Maintenance: Requires minimal upkeep (no painting, sealing, or staining). |

Heat Retention: Can get hot under direct sunlight, making it uncomfortable to walk on.Expensive to install |

|

Water-resistant: Suitable for humid and wet environments. |

Less Natural Look: This doesn’t fully replicate the authentic appearance and feel of natural wood. |

|

Sustainable: Manufactured with recycled plastic and wood fibres, reducing waste. |

Heavier Than Wood: More difficult to transport and install. |

|

Termite & Pest Resistance: Unlike natural wood, WPC isn’t prone to termite damage |

Potential for Scratches & Stains: The surface can be scratched or stained if not properly cared for. |

|

Customizable: Available in various colours, textures, and finishes. |

Less Rigid Than Wood: May sag or warp under extreme weight or poor installation. |

What Are The Common WPC Uses in India?

The material of wood plastic composite refers to a blend of sawdust and plastic that carries the durability of plastic, and the aesthetics of wood. The material has gained significant popularity in recent years due to its performance and excellence in a wide variety of diverse industries. Some of the common uses of WPC in the construction industry include the following:

-

WPC Furniture

With the waterproof nature and strength capabilities of the wood polymer composite boards, they prove to be wonderful choices for the manufacturing of diverse furniture elements such as tables, kitchen cabinets, chairs, shelves, and others. They ensure the creation of a smooth surface and sturdy furniture that are easy to paint or stain with a captivating visual appeal and long-term efficiency.

-

WPC Decking

The WPC decking, a form of WPC board that comes with incredible stability, durability, and the ability to withstand extreme climatic conditions is widely used for a plethora of outdoor applications. The material is designed with features such as water and weather resistance, termite resistance, and low maintenance needs making it a great choice for outdoor applications such as gardens, patios, terraces, balconies, and even poolsides. The anti-slip surface and the reliable performance of the material make it a great choice for outdoor uses.

-

WPC Wall Cladding

The material with its premium features and long-term durability, can also be widely used for cladding applications in both interior and exterior walls. The WPC boards come with a stylish and contemporary appearance along with several options for customization, are easy to install and maintain, and with effective weather resistance serve to be great choices for the building of cladding designs for walls, roofs, fences, etc. They help in the creation of innovative designs along with practicality in structures.

-

WPC Flooring

The WPC boards are also widely used as a reliable flooring option with their remarkable aesthetic appeal that mimics the look of wood, the resistance properties against moisture, water, and even termites, and the durability that lasts generations. The WPC serves to be a great choice for manufacturing interior floors in homes, office interior designs, and other spaces.

-

WPC Ceiling and Wall Paneling

With the sophisticated and stylish appearance and the weather-resistant features of the WPC boards, the material is widely used for wall panelling and ceiling applications as well. They can be used in kitchen designs, bathrooms, and bedrooms with effective resistance to moisture and can also be used as an innovative ceiling design for residential or commercial buildings. They are incredibly low maintenance and ensure reliable long-term performance in homes and other spaces.

-

WPC Doors and Windows

The material WPC is also a preferred choice for manufacturing high-performance doors and windows that come with premium features like corrosion resistance and to withstand extreme conditions without warping, cracking, and other damages. You can get the innovative and unique styles of the WPC doors and windows with wide customization options, moisture and fire-resistant properties, effective noise insulation, and easy-to-install and maintain benefits.

How Much Does the Material of WPC Cost in India?

The WPC board cost in India varies depending on several factors, some of which are as follows:

- Quality

- Quantity

- Thickness

- Application

- Location

- Supplier

You can refer to our website or consult the local suppliers for accurate prices but here we have provided a rough estimate of the WPC cost structure in India.

|

WPC Types |

WPC Cost in India |

|

PE WPC (Polyethylene-based WPC) |

₹160 per sq. ft. (varies by thickness) |

|

PP WPC (Polypropylene-based WPC) |

₹150 – ₹250 per sq. ft. (varies by thickness) |

|

PVC WPC (Polyvinyl Chloride-based WPC) |

₹84 per sq. ft. (for PVC WPC foam boards) |

|

PLA WPC (Polylactic Acid-based WPC) |

₹280 – ₹450 per kg (PLA granules) |

Get High-Quality WPC Doors and Construction Products For Reliable Performance

The wood-plastic composite refers to a kind of advanced material that is used as a substitute for traditional wood due to its excellent standards of durability, eco-friendliness, and low upkeep requirements. The material is widely used in a plethora of different industries ranging from construction to furniture and even automotive industries. You can build customized designs and benefit from the remarkable features of the WPC doors, cabinets, panelling, cladding options, and numerous other products. With an affordable price range and long-term reliability, the WPC boards serve to be smart investments in the present competitive industry.

Suggested Post: What is Plywood? – Plywood Types and Its Uses

FAQ’S

Q:1 Is WPC 100% waterproof?

A:1 Yes, the material of WPC is 100% waterproof. This makes the material ideal for diverse applications in kitchens, bathrooms, and outdoor applications.

Q:2 What is the cost of the WPC board per sq ft?

A:2 The WPC cost is influenced by factors such as quality, brand, purpose, and numerous others. The price typically ranges from ₹80 to ₹250 per sq ft with additional costs for premium grades or features.

Q:3 Is WPC better than plywood?

A:3 Between, WPC and plywood, WPC is an incredible option with properties like resistance to moisture, termites, fungi, and others along with enhanced longevity. However, plywood can be a better choice for heavy-duty uses due to the superior levels of strength and sturdiness it offers.

Post A Comment