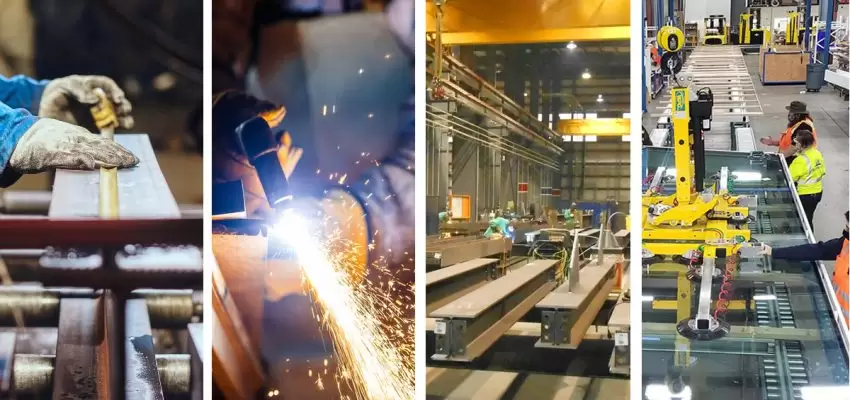

Today, in the construction and manufacturing industry, fabricators play a huge role in providing customized solutions for specific applications. The array of materials that fabricators work with, from metals to glass and plastics, can be used to create anything – from intricate designs to structural components. In this blog, several types of fabricators will be discussed, and their processes, applications, and importance in numerous industries will be discussed.

Post your Requirement

What Are Fabricators?

Fabricators are companies or professionals who manufacture customized products from raw materials by cutting, shaping, welding, assembling, etc. through various operations. These individuals form a very important place within industries as they provide customized products for clients based upon specific requirements, be it regarding structural construction or minute architecture designs. They handle materials like metals, glass, plastics, and composites. Their experience allows them to create high-quality, durable products that also meet not just safety and regulatory compliance but client expectations as well.

Types of Fabricators And Their Tasks

1. Aluminum Fabricator

Aluminium fabricators specialize in aluminium-based transformation into a variety of customized products such as window frames, door systems, and even very complex architectural details. Aluminium is inherently lightweight while being resistant to corrosion, making it an excellent material of choice for many applications, mainly in construction. The process of fabrication comprises various major techniques, including cutting, which sizes aluminium sheets or extrusions precisely; and welding, in which pieces are joined securely using methods like MIG or TIG welding. Finishing techniques, like anodizing or powder coating, also further enhance the aesthetic qualities and durability of the final products. These custom solutions are commonly applied in residential and commercial construction, considering the versatility of aluminium is also a pertinent factor when it comes to architectural design.

2. Gate Fabricators

Gate fabricators specialize in designing and making custom gates for residential, commercial, and industrial use. They work with extensive material ranges, from wrought iron and steel to wood, for an incredibly broad range of styles, from ornate and decoratively patterned to minimalist and super minimalist. Their manufacturing process very often incorporates metal working precision, like cutting and welding processes, to ensure that any given gate is pleasing to the eye but also strong and secure. Many gate fabricators also include automation systems, which makes them highly accessible and also enhances their features of security. Because of that, these custom gates offer dual purposes within properties and incorporate security plus aesthetic upgrades.

3. Glass Fabricator

Glass fabricators are specialized craftsmen whose craft pertains to the cutting, shaping, and finishing of glass products to achieve special design and functional specifications. From shower enclosures and glass doors to large storefront windows, their services range to everything. Advanced techniques such as heating the glass at a controlled rate in fabrication; and the annealing effect, which deals with the cooling of the glass to make it stronger, are involved in the laminating of layers of glass and protective films together for strengthened safety. With the popularity of modern architectures emphasizing transparency and natural light, energy-efficient glass fabrication that promotes aesthetically pleasing solutions that also comply with performance standards is the need of the hour.

4. Glass Processor

Glass processors refine and enhance glass products through different special techniques of specialized techniques. Unlike the older glass fabricators, the glass processors focus more on the fine finishing of glass. This may range from cutting, drilling, and polishing to the application of coatings. Processes in this industry have allowed them to manufacture products that are fit for glass doors, interior partitions, and custom glazing solutions. The paramount safety requirements and aesthetic appeals of the final product reflect a great need for this industry. With current technology and adherence to relevant industry rules, glass processors meaningfully contribute to the construction and interior design fields through the implementation of complex architectural visions.

5. Grill Fabricators

Grill fabricators specialize in designs of custom grills and produce grills that range from the simplest outdoor cooking stations to the most elaborate built-in grill systems. Their products range from short, simple outdoor cooking stations to extensive built-in grill systems, ensuring durability and heat resistance in the product. The materials the fabricator chooses are mainly high-grade stainless steel and cast iron. In the design phase, grill functionality, size, and style need to be seriously taken care of when a particular preference of the chef or home cook needs to be met. Thus, grill fabricators not only provide beneficial cooking appliances but also bring style to outdoor spaces through custom solutions.

6. Metal Fabricator

Metal fabricators deal with a wide diversity of metals, steel, aluminium, and copper, to name a few in the creation of components and structures in various industries. The main aspects of their fabrication process may include cutting, bending, welding, and assembling metal parts according to the specific project requirements. In the sectors of construction, automotive, and aerospace, metal fabricators are crucial and make everything from structural beams and brackets to custom machinery parts. Their adaptation to different specifications of projects makes them irreplaceable in the delivery of high-quality, tailored solutions for every industry’s unique needs.

7. Railing Fabricator

Railing fabricators are highly skilled in the production and design of railings in terms of aesthetic beauty and safety features. Common materials used when railing is fabricated include steel, aluminium, and glass; in that regard, there is a variety of railings appropriate for residential, commercial, or public constructions. The manufacturing process mainly utilizes precision cutting and welding to ensure that the railings look both strong and secure but also aesthetically pleasing. The railings are essential in making a space appear better, whereas the primary necessary safety feature on staircases, balconies, and walkways also contributes to the architectural character of a building.

8. Steel Fabricators

Steel fabricators are professionals who produce a wide range of structures and parts in multiple applications. Their production includes the major building frameworks, industrial machinery, and even custom structural parts. Fabrication is a process that usually involves precise cutting, welding, and finishing techniques that ensure the final piece will meet very particular engineering standards and performance criteria. As with its durability and strength, steel continues to form one of the primary choices for construction and manufacturing since it contributes to long-lasting durability and stability in a variety of applications. Steel fabricators also play a critical role in supporting the construction industry by enabling incredible architectural designs.

9. Structural Glazing

Structural glazing is a specialized fabrication technique involving the use of glass as a structural element in buildings; this allows for the creation of visually spectacular glass facades and roofs. This technique does not only give a beauty implication to a structure but also adds to the functionality aspect of the same. The manufacturing process entails sophisticated techniques to ensure that the glass end product can carry weight and withstand natural conditions like wind and earthquakes. Manufacturers involved in this industry are expected to meet stringent safety and engineering standards to ensure the final manufactured products are safe and highly reliable. Structural glazing has become a fashionable topic in modern architecture, with the trend of enlightenment, space, and transparency in designs.

10. Structural Steel Fabricators

Structural steel fabricators have created specific businesses focused on the production of steel structures that give essential support to buildings, including steel structures, and big projects. Such manufactured items include beams, columns, and trusses engineered to withstand varying loads and stresses. In the manufacturing process, precision cutting and welding would be employed to ensure structural strength, along with other measures of quality control aimed at reaching industry standards. There is probably no better proof of this than in skyscrapers and big bridges for example. They are essential to the basic building blocks that architects and builders use to push the boundaries of design.

11. uPVC Fabricators

The material of unplasticized polyvinyl chloride (uPVC) possesses wonderful thermal as well as acoustic insulation capabilities which makes it a preferred choice among the people. The uPVC fabricators are the professionals who ensure procurement of quality uPVC, cut it in sections, mend, and assemble these sections to create durable and energy-efficient products, mainly used in windows and doors. uPVC does not require much maintenance and has a long life span, which increases its usage in both residential as well as commercial areas. The very process of fabrication of uPVC products involves fine craftsmanship techniques to ensure strict compliance with performance standards so that clients are provided with reliable solutions towards energy efficiency, thereby contributing to comfortable living and working environments.

Benefits Of Working With Fabricators

- Customized Fabrication Solutions: The fabricators can offer a customized solution to the project. It means in such customization that the final product will be according to the vision and functionality of the client.

- Expertise And Quality: Fabricators ensure quality workmanship and safety standards with low chances of defects and failure. This is mainly because they possess special skills and knowledge.

- Efficient Production: Fabricators can ensure productive manufacturing processes, thus shorter production schedules, and reduced prospects for delay to complete the project.

- Cost Effectiveness: By directly dealing with fabricators, clients are able to avoid the middlemen and spend less money on the overall output of the project, yet the quality will not be compromised.

- Forward Thinking: Fabricators are usually the first to adapt to new techniques and materials and can provide innovative solutions to enhance project outcomes.

Approximate Cost Charged by Fabricators

|

Type of Fabricator |

Approximate Cost (INR) |

Notes |

| Aluminium Fabricator | ₹500 to ₹2,500 per hour | Costs vary based on complexity and finishing options like anodizing or powder coating. |

| Gate Fabricator | ₹8,000 to ₹50,000 per gate | Varies based on materials (wrought iron, wood), size, and design intricacies. |

| Glass Fabricator | ₹800 to ₹4,000 per square foot | Prices depend on type (tempered, laminated), thickness, and custom shapes. |

| Glass Processor | ₹1,000 to ₹3,000 per square foot | Similar to glass fabrication, with additional costs for drilling or custom coatings. |

| Grill Fabricator | ₹10,000 to ₹60,000 per grill | Influenced by materials (stainless steel, cast iron) and design features. |

| Metal Fabricator | ₹600 to ₹2,500 per hour | Prices depend on metal type, project complexity, and finishing requirements. |

| Railing Fabricator | ₹800 to ₹3,000 per linear foot | Varies with material (steel, aluminium, glass) and design complexity. |

| Steel Fabricator | ₹600 to ₹2,500 per hour | Prices vary based on the type of steel and project complexity. |

| Structural Glazing | ₹1,200 to ₹5,000 per square foot | Costs depend on glass type and structural requirements. |

| Structural Steel Fabricator | ₹80 to ₹200 per kg | Prices vary based on the size and complexity of the structure. |

| uPVC Fabricator | ₹8,000 to ₹25,000 per window/door unit | Costs depend on size, design, and energy efficiency features. |

Conclusion

Fabricators play a vital role in modern manufacturing and construction – providing intrinsic services that create an architectural vision. From aluminium and glass to steel and uPVC, a unique part is played in delivering customized goods to satisfy diversified clientele by each sort of fabricator. They achieve top-quality results customized to their requirements by working with skilled fabricators. Wider recognition of the skills of fabricators adds efficiency to a project, as well as assurance that the final products will be durable, safe, and aesthetically beautiful. Whether you are undertaking new construction or seeking custom solutions, working with fabricators can be the smartest investment because it can take your results to the next level.

Read Also: 8 Factors To Consider When Hiring a Metal Fabricator

Post A Comment