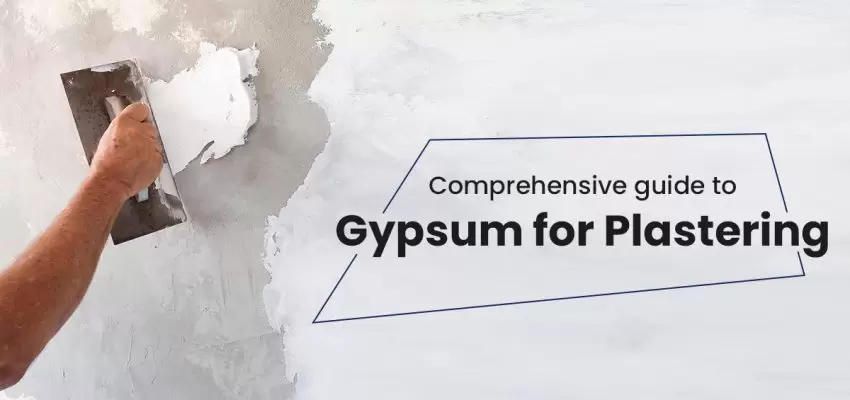

Gypsum plaster has emerged as an optimal solution for achieving smooth, attractive wall and ceiling surfaces during construction projects. This complete guide delves into the gypsum plastering process, unpacking its benefits, considerations for choosing suitable gypsum plaster products, application techniques, and durability. We will examine why gypsum plaster allows for time and cost-efficient application while resisting cracks and other damage over time. You’ll learn best practices for leveraging gypsum plaster’s versatility, workability, and strength through every step from selection to finish coat. With the knowledge provided here, it’s easy to see why quality, efficiency, and aesthetic vision drive the growing popularity of gypsum plastering.

Post your Requirement

What is Gypsum Plastering in Construction?

Gypsum plastering involves applying a plaster made from gypsum, a mineral found in sedimentary rocks, to masonry walls and uneven surfaces. This versatile technique serves both practical and aesthetic purposes. On a functional level, gypsum plaster enhances durability, insulation, fire resistance, and impact resistance. It also saves construction time and ensures walls have a smooth finish ideal for high-quality paints and wallpapers. Aesthetically, gypsum plaster provides a polished look and feel that elevates the quality of any building. Taking advantage of gypsum’s corrosion resistance, insulating properties, and versatility, gypsum plastering is a go-to method for transforming basic wall structures into durable and visually appealing surfaces.

Different Techniques of Gypsum Plastering

Different techniques of Gypsum Plastering are mentioned below:

Traditional Plastering

Traditional plastering is a time-intensive, manual process performed by skilled craftsmen using gypsum plaster and a trowel. It involves preparing the plaster mix, then applying it in layers to surfaces, smoothing and leveling with a trowel to create an ultra-smooth finish. The key advantage is the classic, artisanal aesthetic appreciated by homeowners and designers for its authenticity and decorative appeal.

However, traditional plastering requires experienced plasterers and quality depends on their skill. Overall, this method provides an unrivaled smooth finish but is labor and skill-intensive.

Shot Blasting

Shot blasting accelerates gypsum plaster application using a spray gun to propel the plaster mix onto surfaces in a fine mist. This plastering method delivers speed, with the spray gun allowing quicker coverage over the traditional manual application with a trowel. The key advantage is faster project turnaround, making shot blasting ideal for large-scale plastering where time efficiency is critical. However, technique mastery is vital, as inconsistency in the spray application or plaster thickness can vary visually. While the spray gun saves labor and time, shot blasting quality still relies on hiring experienced crews who can ensure consistent coverage and smoothness after finishing with a trowel or float.

Dry Lining

Dry lining delivers speed and convenience in gypsum plaster application through a hopper gun that sprays plaster onto surfaces. This technique contrasts traditional manual methods with its quick, efficient coverage allowing tight project turnarounds. While the hopper gun eases rapid application, a key advantage is the seamless, smooth finishes achievable when handled by experts. Their skill controls consistent plaster flow and thickness for a polished look ready for paints or wallpapers.

However, much depends on the plasterer’s experience in manipulating the hopper gun and achieving an impeccable uniform surface. When executed by seasoned pros, dry lining yields remarkable quality within accelerated timelines.

Choosing the Right Gypsum Plaster

Selecting the right gypsum plaster is crucial for a successful plastering project. Consider the following factors:

- Smoothes Imperfections – Creates seamless, blemish-free wall and ceiling finishes.

- Facilitates Customization – Enables specialized plasterwork and ornamental designs.

- Cost-Effective – Saves on materials and labor versus traditional plasters.

- Resilient – Withstands heat, fire, water, and corrosion.

- Efficient Use of Resources – Minimizes labor, fuel, electricity, and water.

- Accelerates Timelines – Sets faster than other plasters.

- Lightweight – Reduces structural stress in high-rises.

- Sound Insulation – Provides noise dampening with acoustic properties.

Top Brands to Consider

Here we have listed the top brands selling gypsum plaster:

How Gypsum Plaster is Prepared

Gypsum plaster is derived from gypsum, a natural mineral found in sedimentary rocks. To produce gypsum plaster, the mineral is ground into a fine powder and heated at high temperatures. This heating process involves the combination of sulfur and oxygen to form sulfate (SO4), which then reacts with calcium and water to create gypsum (CaSO4.2H2O).

Storing Gypsum Plaster

Proper storage is crucial to maintaining the quality of gypsum plaster: Carefully follow these steps:

- Store plaster bags on an elevated surface away from walls to prevent exposure to water or moisture.

- Avoid exposing bags to moisture, as it can impact the setting time and strength of the plaster.

- Store bags on a sealed surface and ensure they do not come in contact with water or moisture.

- The shelf life of gypsum plaster is approximately 3-4 months from the date of manufacture but can be extended with proper storage.

Application Process of Gypsum Plaster

During application, follow these tips for effective gypsum plastering:

- Fix surface imperfections: Before applying gypsum plaster, it’s crucial to fix any cracks, holes, and seams on the surface. This ensures a smooth finish and prevents any future issues.

- Proper mixing technique: When mixing plaster with water, always add the plaster to the water and not the other way around. This helps prevent the formation of lumps. Mix the plaster and water thoroughly for 1-2 minutes, ensuring a consistent and homogenous mixture.

- Optimal mixing time: It’s important to complete the mixing process within 1-2 minutes. Over-mixing can affect the consistency of the plaster, while under-mixing may cause separation and peeling once applied. Find the right balance to achieve the desired results.

- Water temperature: Always use room temperature water when mixing plaster. Using hot water can cause the plaster to quickly grow, making it difficult to work with and achieve a smooth finish. Similarly, extremely cold water can make the mixing process challenging.

- Avoid prolonged soaking: Do not soak the plaster in water for an extended period. This can cause the plaster to settle and harden, making it unusable. Follow the manufacturer’s instructions for the recommended soaking time, if any.

- Clean tools and equipment: To ensure optimal plaster quality, it’s important to clean your buckets, and tools, and use uncontaminated water at each step of the process. Dirty equipment or contaminated water can negatively impact the final result, so make sure to clean everything thoroughly.

Gypsum plaster has a long history of durability, as seen in structures like the Giza pyramids and historic buildings in Britain. Unlike cement plasters, gypsum plasters are resistant to cracks, reducing the need for frequent maintenance and repairs. This versatile material has been used in construction since the 15th-16th century and continues to be a popular choice due to its numerous benefits. Shifting to gypsum plasters can result in significant cost and time savings, making it a revolutionary option in the construction industry. Embrace this trend and enjoy the durability, aesthetics, and efficiency that gypsum plaster offers.

FAQs

Q-1. Is gypsum good for plastering?

A-1. Yes, gypsum is excellent for plastering due to its good workability, quick set time, and smooth finish.

Q-2. Why is gypsum used for plaster?

A-2. Gypsum is used in plaster for its binding properties and to create a smooth, durable surface on walls and ceilings.

Q-3. Is gypsum plaster cheaper than cement?

A-3. Generally yes, gypsum plaster tends to be more cost-effective than cement plaster due to easier application and shorter curing times.

Q-4. How long does gypsum plaster last?

A-4. Gypsum plaster can last over 50 years with proper application, favorable conditions, and ongoing maintenance.

Post A Comment