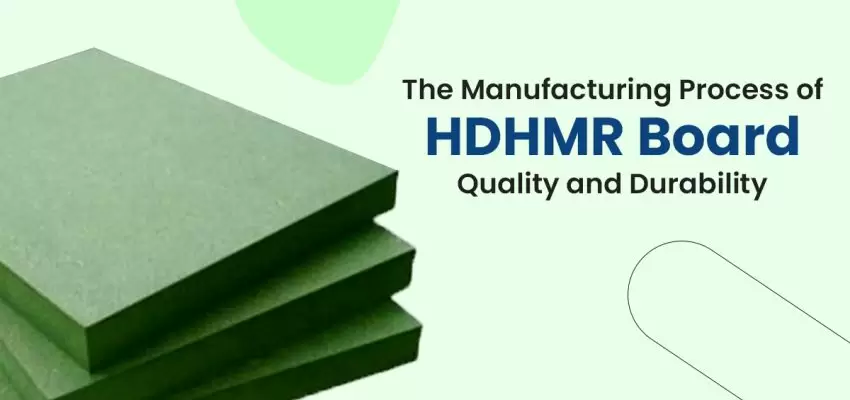

In the dynamic realm of construction and design, the advent of High-Density moisture-resistant (HDHMR) boards has revolutionised traditional approaches. These boards have swiftly become the preferred choice, celebrated for their superior quality, remarkable toughness, resistance to moisture, and imperviousness to pests. As architects, interior designers, and homeowners seek construction materials that not only endure the test of time but also offer innovative applications, HDHMR boards have emerged as a transformative force in the industry.

Post your Requirement

In this comprehensive exploration, we delve into the intricate world of the manufacturing process of HDHMR boards, focusing on the aspects that define their quality and durability. Unlike conventional plywood, HDHMR boards stand out for their enhanced reliability, durability, and adaptability to challenging conditions. This blog aims to unravel the manufacturing techniques, properties, uses, and advantages of HDHMR boards, shedding light on why they have become pivotal players in reshaping the landscape of construction projects. Join us on this journey as we navigate through the intricate process that culminates in the creation of HDHMR boards, embodying a commitment to excellence, sustainability, and a paradigm shift in construction practices.

Read in Detail: What Is HDHMR board? An Ultimate Guide To HDHMR Board

HDHMR Boards Vs. Plywood

When comparing HDHMR boards to plywood, distinct differences emerge, showcasing the superior qualities of HDHMR. HDHMR boards are crafted from superior-quality wood, making them exceptionally tough. They are not susceptible to termite, borer, or fungus attacks, and their high resistance to moisture sets them apart. Moreover, they offer innovative applications, contributing to their growing popularity. In contrast, plywood is constructed from inferior-quality wood and lacks the toughness exhibited by HDHMR. Plywood is susceptible to issues such as termite, borer, and fungus attacks, and it is significantly affected by moisture and humidity. Plywood also falls short when it comes to innovative applications. These differences position HDHMR as the superior choice for various applications, showcasing its potential to redefine the construction industry.

Read Also: What Is Difference Between Plywood And Plyboard?

Types Of HDHMR Boards

Here we have stated the types of HDHMR boards:

- Plain HDHMR Board: The versatility of plain HDHMR boards makes them suitable for various purposes, even when intricate designs or unusual shapes are required. Carving and shaping these boards is easy, and they maintain their strength and durability even in tough conditions. With a consistent fibre density throughout, they are ideal for uniform applications.

- Pre-Laminated HDHMR Board: Pre-laminated HDHMR boards offer a perfect solution for crafting doors, including designer and flush doors. They serve as a smart alternative to traditional solid doors and provide opportunities for enhancing flush doors with unique surface designs, customized patterns, attractive finishes, and matching door frames.

Properties Of HDHMR Boards

Understanding the properties of HDHMR boards provides insights into why they are preferred over traditional materials like plywood.

Following are some of its properties:

- Strong Hold: HDHMR boards can tightly hold screws due to their even inside, making them tough and reliable.

- Super Tough: Crafted from strong wood and special glue pressing, these boards are exceptionally hard and solid.

- Bug-Proof: Treated to keep away termites and borers, HDHMR boards alleviate concerns about insects causing damage.

- Sturdier Than Plywood: These boards surpass plywood in toughness, handling more wear and tear effectively.

- Eco-Friendly: HDHMR boards contribute to environmental sustainability, being made from tree parts, farm waste, and leftover wood from forests.

- No Splinters: Working with HDHMR boards is safe, as they do not produce splinters or chip-offs.

- Water-resistant: Their construction allows them to handle water better than plywood, reducing the risk of damage.

- Smooth Finish: HDHMR boards boast a smooth finish without any bubbles, offering a polished appearance.

- Cost-Effective: Costing less than other materials, HDHMR boards provide a budget-friendly solution for various projects.

Uses of HDHMR Boards

The versatility of HDHMR boards extends to various construction and design applications, positioning them as a preferred choice over traditional materials like plywood. They serve as integral components in constructing kitchen cabinets, doors, floors, closets, outdoor fixtures, shelves, and more. HDHMR boards even find applications as substitutes for regular doors, showcasing their adaptability and potential to replace other materials in specific areas, such as kitchens and floors.

Advantages Of Using HDHMR Board

Understanding the advantages of using HDHMR boards sheds light on why they are gaining popularity among professionals and homeowners alike. Advantages of using HDHMR Boards include:

- Enhanced Durability: HDHMR panels outlast plywood, reducing the need for frequent replacements.

- Water-Resistant Reliability: Suitable for highly moist areas and climates, these panels maintain their integrity in challenging environments.

- Superior Material: Crafted from hard eucalyptus wood, HDHMR panels boast higher density, ensuring a sturdy and robust product.

- Precise Routing: No core gaps make these panels an ideal substrate for precise and sharp cutting and routing, resulting in clean edges.

- Strength and Consistency: Uniform density gradient and a compact core provide enhanced screw and withdrawal strength, improving overall reliability.

- Tailored to Indian Climate: Specially formulated glue enhances water resistance, making HDHMR panels ideal for Indian weather conditions.

- Smooth and Ready Surface: These panels come with a smooth surface that can be easily polished with a variety of colours, reducing paint consumption and cost.

- Aesthetic Enhancement: HDHMR panels offer innovative applications that add aesthetic value to finished products, elevating the overall look and feel.

- Cost-Efficiency: HDHMR panels provide a cost-effective solution for paneling, combining durability and versatility with affordability.

Top Brands Selling HDHMR Boards

Several renowned brands offer HDHMR boards, ensuring consumers have access to high-quality options. Some of the top brands include Action Tesa, Adlerwud, Century Prowud, Crossbond, and Greenply.

Conclusion

The manufacturing process, properties, uses, and advantages of HDHMR boards highlight their significance in the construction and design industry. As professionals and homeowners increasingly choose HDHMR over plywood, these boards promise better and longer-lasting results for future projects. Their adaptability, durability, and cost-effectiveness position them as game-changers, reshaping the way construction projects are approached.

Read Also: HDHMR Boards: Contemporary Trends in Design and Construction

Post A Comment