-

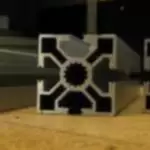

- An ‘Extruder’ is an extruding machine that is used to extrude metals like copper, steel, aluminum and plastics. Some brittle metals can be extruded very easily through the extruder. The main function of an extruder is conversion of raw material directly into finished goods ready for supply and packaging.

- In the extruding process the extruder creates enough pressure in the billet such that it can forcefully push or pull the material through the cross section of the die orifice and extrude the finished product.

- The extruder extrudes shapes of constant cross section and thickness and both hollow as well as solid sections. The extruder can extrude continuous cross sections of the finished product or semi continuous cross sections depending on the sizes and application of the extruded product.

- The Hot and Cold method is primarily used for metal extrusion. Some metals are melted completely before the process of extrusion and some metals are cold pressed also known as forging. Aluminum is the most common metal to be extruded. This process increases the material strength of the object that is extruded.

- A person operating the machinery for the same is called ‘Extruder operator’.

Loading…

What is an Extruder?

By: Team McCoy Mart | June 15, 2016 | Last Updated: May 25, 2024 | 1 minute read

Post A Comment