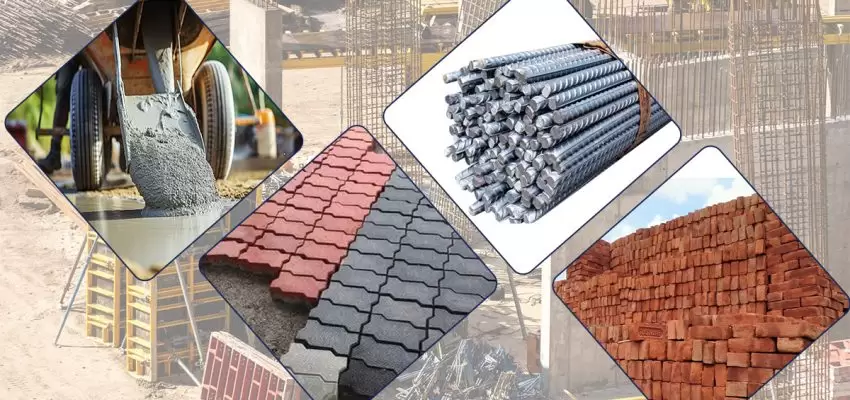

In the era of the construction industry, the building material is a substance extensively used in diverse structures. From robustness to aesthetic finishes, there are various kinds of materials extensively used in diverse industries. We often use different types of construction materials owing to their structural capabilities. In diverse regions of India, there are local and national standards that govern components.

Post your Requirement

On the other hand, builders and architects opt for different building components depending on their various requirements, aesthetics, and costs. Choosing the right and best-fit building materials for your construction project means increasing and lengthening the project’s durability. In this blog, we are going to discuss the types of building materials.

1. TMT Bars:

TMT (Thermo mechanically treated) bars are durable and robust reinforcement bars used in the construction of concrete to improve the structural integrity and weight-lifting capacity of any infrastructure or building. These TMT bars are produced after a stringent manufacturing process, imparting them with excellent automatic properties such as ductility, robustness, and corrosion resistance. These robust bars are manufactured in various diameters and grades to meet specific needs, assuring the builders and engineers with a trustworthy and durable solution for strengthening concrete structures with eco-conscious conditions and dynamic loads.

The Following Uses Of TMT Bars In The Construction Industry:-

- Strengthening the concrete frames for durability, robustness, and strength.

- Improving the seismic opposition of the buildings.

- It helps with the heavy loads in commercial and industrial buildings.

- Reinforcing bases for high-rise structures.

- They always ensure structural integrity in corrosive environments.

- They also improve the durability and robustness of any infrastructure.

- They also lower the use of the material and maintenance needs.

- Enabling efficient and economical building design material solutions.

2. Ready Mix Concrete:

Premixed concrete, commonly referred to as Ready mix concrete is a type of concrete that is produced in a batch plant. It is a formulated mixture of cement, water, aggregates, and other supplementary components, that is produced off-site in a controlled environment.

Ready Mix Concrete is tailor-made concrete for specific project needs and is transported to the location of the building in the transit mixers. The benefits of opting for ready-to-mix concrete are many, including quality assurance, decreased labor requirements, and improved construction speed. By stopping the need for on-site mixing and batching, it minimizes the wastage of components wastage and consequently, assures the optimal use of resources.

The Following Uses Of Ready Mix Concrete:-

- The base for the building of the construction and other structures.

- Design and manufacturing of the slabs and beams.

- It is also used in the building of bridges, Highways, and roads.

- Precast elements such as blocks and panels.

- Industrial warehouses and floorings.

3. Cement:

Cement is one of the most extensively used in the construction industry in various aspects. It is used with the concrete, and mixed to make the cement more durable, sturdy, and robust within budget. In a nutshell, it is the basic element in prominent components for diverse buildings such as concrete, grout, and mortar all around the world. A binder, commonly referred to as cement, is a preeminent chemical substance that is the fundamental component in the diverse building and construction industry, that makes other materials harden, robust and long-lasting.

The Following Uses Of Cement:-

- Infrastructure and base of the era of construction.

- It is also considered the main Foundation for the building and architecture design industry.

- It helps in producing concrete for structural elements such as beams, slabs, and sections.

- It is used in the design and manufacturing of grout for sealing the joints, gaps, and cracks.

- Plaster Production for finishing the diverse interior and exterior bases.

4. Paving Blocks:

Paving blocks or pavers, commonly referred to as paving stones are the brick pieces extensively used for exterior flooring or Block paving. It is used across a comprehensive range for its durability and artistic appearance in the modern flooring design. From their various cobblestone choices and improving the aesthetics and appearance with the sleek design, there are wide ranges of paving blocks in versatility. With outstanding durability and an interlocking design, it also assures maintenance and cost-effectiveness within budget and on time.

The Following Uses Of Paving Blocks In The Construction Industry:-

- The base for the structures and buildings in industry.

- Structure of the sidewalks and Pavements.

- It is used to construct bridges and Highways.

- It is also used in the diverse construction industry mainly for Industrial flooring and warehouses.

5. AAC Blocks:

AAC (Autoclaved Aerated Concrete) blocks are modern-day and preeminent materials for buildings described by their lightweight and spongy design. Crafted from sand, cement, aluminum powder, and more, these blocks experience a memorable autoclaving process that facilitates the structure of countless tiny airdrops throughout the components.

This consequently results in blocks that are lightweight, robust yet sturdy. It helps in the outstanding thermal insulation and fascinating soundproofing properties. These blocks are preeminent for their easy installation and handling, assuring rapid building and building while lowering the cost of investment. AAC Blocks are extensively used in specific residential, industrial building, and commercial industries for floors, walls, and other spaces which means more eco-conscious solutions.

The Following Uses Of AAC Blocks:-

- Weight-lifting walls in any residential and commercial space.

- Partition walls for the diverse interior spaces.

- Different fire-resistant walls in high-rise buildings.

- Soundproofing features that assure noise reduction.

- Prefabricated components for quick buildings.

6. Shuttering Plywood:

Shuttering plywood, a vital component in the era of concrete structure, is specially developed for the use of mold for shaping concrete. Its versatility and reusability are the main reasons why it is an essential material for building walls, columns, slabs, and other materials for construction and concrete with their efficiency and precision. This plywood is preeminent for its robustness, high strength, and durability to resist the weight and force/pressure of any concrete with moisture. Consequently, Its smoothness helps in the ease of the removal after the concrete has been applied, leaving behind the smooth and flawless finish on the casted surface.

The Following Uses Of Shuttering Plywood:-

- It helps in producing molds for releasing concrete walls, queues, and beams.

- Producing the molds for custom-shaped concrete details.

- It helps in supporting and stabilizing the concrete during the setting processes.

- It also helps in the production of different reusable formwork plans for economical projects.

How To Choose The Right Material?

Want to ensure the success of your project? Looking to choose the right materials for your building construction? Baffled about choosing the right building components? Here is the right answer. The quality, investment, and safety of your project depend on the choice. If you are choosing an ideal component/ material for building, there are a few essential factors to consider that best fit your specific project requirements. So let’s consider:-

- Cost: The financial investment required for building materials, balancing initial expenses with long-term savings.

- Durability: Material’s ability to withstand wear, tear, and environmental stressors, ensuring longevity and structural integrity.

- Maintenance: The level of upkeep and repairs necessary over time to preserve the material’s condition and functionality.

- Appearance: The aesthetic appeal and visual impact of the material, enhance the overall design and ambiance of the project.

- Location: Consideration of regional climate, terrain, and regulations to select materials suitable for specific geographical conditions.

- Availability of the material: Accessibility and sourcing of materials locally or globally, impacting project timelines and sustainability goals.

- Reputation Of The Provider: Evaluating the track record and credibility of suppliers, ensuring reliability, ethical practices, and quality assurance throughout the project lifecycle.

Conclusion

In a nutshell, these are a few prominent building materials for any residential or commercial project. Choosing the right material completely depends on the salient features, requirements, and your project needs. Every construction material has unique features, characteristics, and diverse requirements. For instance, concrete is extensively used in floors, walls, and structural components, wood is commonly used in the construction industry for interior finishing, flooring, framing, and more. So what are you tet waiting for? Always understand diverse requirements, features, and characteristics of the building materials to understand the best fit for your project.

FAQ’s

Q-1. What is the most durable material for building?

A-1. Cement is considered one of the most preeminent building materials, blended with concrete to give it durability, strength, and robustness in the design and build.

Q-2. What material is used in the construction of buildings?

A-2. There are comprehensive range of quality-made materials for building used in the structure of buildings such as cement, concrete, Paving Blocks, shuttering plywood, etc. However, the choice of the material completely depends on your specific requirements.

Q-3. What is the strongest material for walls?

A-3. Concrete components/ materials are renowned for their durability, sturdiness, and resistance to water and other ecological consequences and impacts, ecological outcomes, etc.

Post A Comment