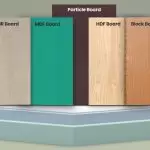

As a builder, contractor, or architect, selecting the right material for structural and finish carpentry applications constitutes an important decision. Two common sheet good options – high-density high moisture resistance (HDHMR) and plywood — both offer versatile solutions for panels, doors, cabinet boxes, furniture, subflooring, and countless other uses. However, confusion exists around whether high-density hardboard or plywood best fits specific project requirements.

Post your Requirement

By examining key performance differences in composition, structure, mechanical attributes, working properties, and cost factors, we can better understand the suitability between these two sheet good workhorses.

| Term | Definition |

| HDHMR |

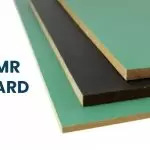

High-Density High Moisture Resistance (HDHMR) is a type of engineered wood product made by compressing wood fibers together under high pressure and heat, combined with special resin and additives to enhance moisture resistance. HDHMR boards offer improved durability and moisture resistance compared to standard MDF or HDF boards. |

| HDHMR Board |

HDHMR boards refer to individual panels or sheets of High-Density High Moisture Resistance material. These boards are commonly used in applications where moisture resistance is essential, such as kitchen cabinets, bathroom vanities, and furniture in humid environments. |

| HDHMR Price |

The price of HDHMR boards varies depending on factors such as thickness, size, brand, and market demand. Generally, HDHMR boards may be priced higher than standard MDF or HDF boards due to their enhanced moisture resistance and durability characteristics. |

| Plywood |

Plywood is a type of engineered wood panel made from thin layers of wood veneer (plys) glued together with adjacent layers having their wood grain rotated up to 90 degrees to one another. Plywood is known for its strength, stability, and versatility and is used in various construction and woodworking projects. |

Let’s explore how HDHMR and plywood compare.

-

Background & Composition:

First, a quick background on the composition of each material:

HDHMR consists of lignocellulosic fibers (wood) consolidated under heat and pressure with resin binders into a dense, fiberboard panel. Wax and other additives improve moisture resistance and machinability. HDF is produced in high-density grades ranging from 800-900 kg/m3.

Plywood comprises thin wood veneers adhered in alternating crosswise grain construction and then bonded under heat and pressure. The layered design inhibits expansion and shrinkage while imparting strength superior to solid wood. Good quality plywood uses waterproof structural adhesives.

With foundational composition differences explained, let’s investigate how these disparate construction methods translate to practical performance distinctions.

-

Density & Weight:

HDHMR’s high consolidation process removes voids, creating an ultra-dense sheet with a consistency similar to solid wood. Plywood’s layered assembly intrinsically incorporates air pockets, resulting in lower density despite thicker panel builds.

Thus, HDHMR (800-900 kg/m3) has up to 50% higher density than plywood (500-700 kg/m3). The denser HDHMR feels heavier and more rigid in hand. Divide large projects into smaller handling sizes if weight becomes problematic.

-

Strength & Stability:

HDHMR’s dense, void-free fiber matrix grants impressive fastener-holding strength similar to solid lumber. Plywood relies on crossband reinforcement between veneers to resist shear forces. Side-by-side comparisons confirm HDHMR’s screw and nail grip outperforms standard plywood.

For stability, HDHMR experiences less expansion/contraction under fluctuating humidity and temperature changes. Plywood remains more susceptible to minor metric creep despite its crossed-grain layers.

-

Moisture & Environmental Resistance:

Resins used in HDHMR improve moisture resistance, but coatings are still recommended for wet area exposure. Water can penetrate cut panel edges and screw holes without additional sealants.

Plywood uses high water-resistant structural adhesives, making it suitable for both interior and protected exterior applications. Exposure edges still need sealing for best results. Properly sealed, plywood handles moisture better overall.

-

Tooling & Machinability:

Smooth composition with tightly bound fibers enables HDHMR to machine, cut, drill, and route as cleanly as solid wood. No tear-out or splintering occurs. Resilient wax additives also prolong tool sharpness.

Plywood’s layered construction risks chipping or splintering along the exposed veneer edges if tools become dull. The multiple laminations can also deflect drill bits or router bits as they transition between layers. Careful feed rates and ultra-sharp cutters are recommended.

-

Shaping & Flexibility:

HDHMR with proper support structures bends reliably to create curved forms. Plywood sheets flex easily for both tight radii bends and broad contours depending on the number of laminations and grain orientation. Plywood offers the most shaping versatility.

-

Finishing Attributes:

HDHMR’s smooth, uniform surface accepts paints, laminates, veneers, and stains consistently without bleed-through. The edges resist chipping or crumbling when worked. Stains penetrate easily.

Plywood may telegraph imperfections like knots or repair scars through coats of paint. Raw plywood edges lack a refined appearance. Pre-treat edges before applying water-based finishes to prevent raised grain.

-

Sustainability Factors and Cost Considerations:

Both HDHMR and plywood use substantial recycled or recovered fiber content during manufacturing. Formaldehyde-free versions exist for added environmental sensitivity. Reuse or recyclability at the end of service life varies case by case.

HDHMR sells at a 10-15% premium over comparable plywood products. However, HDHMR’s denser composition nets a stronger panel per pound. Consider weight-adjusted values when assessing budget impact.

-

Applications Suitability:

With performance factors compared, preferred material selection becomes application-dependent:

-

- Cabinets & Furniture – HDHMR

- Subfloor & Roof Sheathing – Plywood

- High Moisture Areas – Plywood

- Curved Forms – Plywood

- Signs & Displays – HDHMR

- Speaker Boxes – HDHMR

Conclusion

Understanding inherent physical and working property differences between HDHMR and plywood allows better alignment with application suitability. HDHMR performs well thanks to density and stability while plywood offers cost economy along with bending and moisture resistance advantages. Match your project’s functional requirements to the material characteristics to determine the best choice. Both materials play an important role in delivering versatile sheet good solutions.

Post A Comment