The race for high rise buildings began in the nineteenth century in New York and Chicago, as demand for land far outstripped supply. As engineers continued to make breakthroughs in construction methods and technology, the race for making taller buildings never stopped.

Post your Requirement

High rise construction has become shorthand for ambition, success, prosperity and technical achievement. Cities that have built high rise buildings have their own recognized silhouette, whereas other cities are seeking to create their own iconic skylines with a startling range of ever taller, more daring structures.

Along with the height of a building, the risks associated with its construction have also grown manifold. These risks can be categorized into five key components: the groundwork, the frame, the cladding, the mechanical and electrical systems and the lifts. To mitigate these risks, a rigorous command over logistics is required.

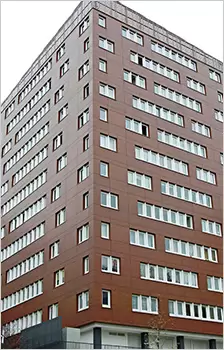

High Rise Facade Design

Enquire Now for Window Frame

Out of these five key components, the facade is by far the most significant. As the primary barrier between the occupants and the elements, the facade system must be strong, fire, water, and wind proof and energy efficient to support a LEED, BREEAM or Green Star rating, all on top of looking good and unique.

However, facade system setup in a high rise building poses a lot of challenges. The main issues that must be addressed relate to the logistical problems faced while installing the façade system and the stability of the facade system under trying conditions.

High-rise buildings have become architectural marvels that define modern city skylines. Their intricate facades not only add aesthetic appeal but also play a critical role in ensuring the safety, sustainability, and comfort of occupants. However, constructing facades for tall buildings comes with a unique set of challenges.

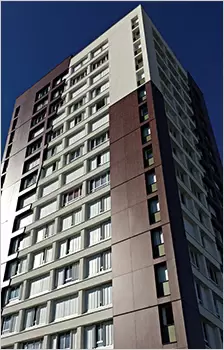

High Rise Facade Jain Heights, Bangalore, India

Rising majestically againdesigns, these towering structures embody modern urban living. However, behind their striking exteriors lies a complex world of engineering challenges that must be meticulously conquered. In this exploration of high-rise facade construction, we delve into the intensive obstacles faced by engineers as they strive to reach new heights of innovation, safety, and sustainability.st the horizon, high-rise buildings stand as awe-inspiring symbols of human ingenuity and architectural brilliance. From shimmering glass facades to futuristic Join us on this journey as we unveil the secrets behind the seamless combination of art and science that enhances the skies with breathtaking skyscrapers.

Enquire Now for HPL

Challenges Faced During High Rise Facade Construction

-

Wind Loads and Structural Integrity:

One of the most significant challenges in high-rise facade construction is dealing with wind loads. As buildings reach unprecedented heights, they encounter stronger wind forces that can put immense pressure on the facade. Engineers must consider factors like wind direction, wind speed, and turbulence to design a facade that can withstand these forces without compromising structural integrity.

-

- Solution: Computational fluid dynamics (CFD) simulations are employed to predict wind behavior around the building. Engineers use this data to optimize the facade design, incorporating features like aerodynamic shapes, wind baffles, and tuned mass dampers to reduce wind-induced stresses.

-

Thermal Performance and Energy Efficiency:

High-rise buildings often face extreme temperature variations between different levels, resulting in uneven heating or cooling. Maintaining a consistent indoor environment becomes a challenging task, impacting energy efficiency.

-

- Solution: Engineers implement double or triple glazing, low-emissivity coatings, and advanced insulation materials to enhance the thermal performance of the facade. Additionally, innovative sun-shading systems and natural ventilation designs are incorporated to minimize energy consumption.

-

Material Selection and Installation:

Selecting appropriate facade materials that can withstand the forces imposed on tall buildings is crucial. Moreover, the logistics of transporting and installing materials at great heights add complexity to the construction process.

-

- Solution: Lightweight but robust materials like glass-fiber composites and high-strength aluminum alloys are favored for their durability and ease of installation. Prefabrication and modular construction techniques are also employed to reduce on-site work and enhance efficiency.

-

Structural Movements and Building Settling:

Tall buildings can experience structural movements and settling due to various factors like temperature changes, foundation settlement, and material creep. These movements must be accommodated by the facade to prevent cracking or leakage.

-

- Solution: Flexible facade systems are designed with expansion joints and movable connections to allow controlled movement without compromising the building’s integrity. Additionally, real-time monitoring systems are installed to detect any excessive movements and assess the facade’s performance over time.

-

Safety Considerations:

High-rise facade construction involves working at considerable heights, posing safety risks to construction workers and the public below. Ensuring the safety of workers during installation and maintenance is of the utmost importance.

-

- Solution: Strict safety protocols, including the use of harnesses, safety nets, and guardrails, are implemented during construction. Maintenance systems like building maintenance units (BMUs) and rope access techniques are employed for regular cleaning and repairs.

The Unitized System: Revolutionizing High-Rise Facade Construction

In the quest for efficiency, speed, and precision in high-rise facade construction, the unitized system has emerged as a game-changing solution. Embraced by architects and engineers alike, this innovative approach has revolutionized the way tall buildings are enveloped, paving the way for sleek, contemporary designs that redefine city skylines.

Benefits of the Unitized System:

-

Speed and Efficiency:

With the assembly of facade units taking place simultaneously with on-site foundation and structural work, the construction process gains remarkable speed. This time-saving advantage not only accelerates project completion but also reduces overall labor costs.

-

Quality Control:

Fabricating facade components in factory settings allows for meticulous quality control and precise manufacturing. Engineers can ensure that each unit meets strict standards, resulting in a consistent and flawless facade installation.

-

Safety and Site Minimization:

The majority of unitized system construction occurs off-site, minimizing on-site risks and congestion. This translates into a safer work environment for construction teams and a reduced impact on surrounding areas during development.

-

Weather Independence:

Since the units arrive on-site as pre-assembled modules, construction is less dependent on weather conditions. This resilience against weather delays enables continuous progress, even in adverse climatic situations.

-

Enhanced Thermal and Acoustic Performance:

The unitized system facilitates the integration of advanced insulation materials and acoustic features within the factory environment. This ensures that the building’s thermal and acoustic performance requirements are met with precision.

One of the ways to offset the logistical issues is through the implementation of a Unitized facade system. Unitized facade installation systems entail serial production and factory fabrication, and assembly of panels. These completed units are then hung on the building structure to form the building enclosure. This permits rapid and economical implementation for buildings of any size, whilst simultaneously enabling creative diversity and a delicate appearance.

The Unitized system is the most cost effective, high quality and quick installation exterior facade system available. A Unitized HPL system comprises of HPL panels mounted onto a prefabricated aluminium frame. Most of the system components are assembled in a plant under controlled working conditions. This promotes quality assembly and allows for fabrication lead-time and rapid closure of the building.

The Unitized system is assembled on the building as panels. The panels are installed in single fashion, starting either from the bottom or top of the building and going around each floor until the whole building is dressed up.

The Unitized system offers many advantages with respect to quality assembly and speed up the site construction time. By design, the system allows for waste reduction in the building process: facade installation is decoupled, and can thus progress separately from other trades’ work, while itself proceeding in a continuous flow process.

Various kinds of waste are reduced, for example:

- Inventory: No on-floor staging will be needed since façade elements are transported via the system directly to the elements’ installation positions or to their dedicated staging area, thereby not affecting space on the ground or inside the building.

- Transportation: On-site transport will be minimized by lifting the façade elements directly from the truck onto the system and forwarding them to their installation positions, without any interim on-floor staging. This avoids internal transportation.

- Waiting: Installing the facade system independently of the site crane and hoist, and freeing up floor space area for others, reduces the waiting time for the façade installers and for other contractors.

- Defects: Risks of damaging the façade elements will be reduced given that no onground or on-floor staging is necessary and that there is full control over on-site transports using fully integrated equipment.

- Motion: The system will have equipment that handles the material flow through the whole process; from factory to installation point. Thereby, contractors will not be subject to unnecessary handling or reliance on potentially unsuitable lifts.

All exterior walls, of whatever materials, are subject to, and must withstand the ravaging effects of nature. These nature forces are sunlight, temperature, water, wind and gravity. All of them must be considered, and their effects provided for, in all locations. They may act upon the wall either individually or more often in combination, but to understand their impact on design requirements the effects of each should be separately examined. The façade system must prove itself to be extremely stable to all external conditions faced by high rise buildings.

For overall facade design using a Unitized façade system the following general parameters should be considered:

- Architectural requirements/restrictions

- Thermal performance to be achieved (U-value,g-value, layer temperatures)

- Flexibility (adjustable performance)

- Interaction strategy with HVAC systems(extract rate, natural ventilation)

Apart from these parameters of a more general nature, the following more specific parameters have significant impact on possible design and, therefore, façade performance:

- Loads

- Maintenance (interior or exterior)

- Investment vs. running costs (integrated view)

For high rise buildings in particular, the wind load plays a significant role in dictating the structural strength and in determining the thickness of the cladding material and the support structures used. All of these parameters must be considered and their impact calculated prior to the fabrication of panels in a Unitized system. Before using any specific cladding material, a thorough testing must be done as per the ASTM standards. All of these requirements and strict quality norms have led to technological innovations including the introduction of new cladding materials for building high rises. Compact Laminates is one such material that can withstand the external load pressures and provide adequate thermal performance due to its sustainable and robust properties while at the same time maintaining the aesthetic look of the building.

Enquire Now for Cladding

Wind load plays a significant role in dictating the structural strength

Designing a facade system today encompasses structural engineering, building physics, materials science, weatherproofing technology, architectural detailing, production engineering, construction management and buildability. The façade also accounts for a significant proportion of project costs, so the engineer’s role is to balance visual and performance requirements to create an economically viable solution that can be built safely. High-rise façades are becoming even more complicated as architects abandon the glass box in favour of ambitious multifaceted forms.

Engineering high-rise buildings is half art, half science – an artful application of science empowered by experience. If done correctly by mitigating the risks involved at every stage, it gives you an enjoyment that you may not have in other fields of endeavour – you can see the results.

Conclusion

High-rise facade construction presents a unique set of challenges that demand innovative engineering solutions. As skyscrapers continue to soar to new heights, engineers strive to overcome wind loads, ensure thermal efficiency, choose suitable materials, address structural movements, and prioritize safety. By conquering these challenges, architects and engineers can continue shaping iconic city skylines while delivering sustainable and safe high-rise buildings for future generations. Incorporating specific parameters into the facade design process is crucial for achieving optimal performance, functionality, and aesthetics. By carefully considering the above mentioned facts, architects and engineers can create facades that not only withstand the ravaging effects of nature but also enhance the overall performance and sustainability of the building.

Post A Comment