Any architect or construction professional can tell you the importance of different types of screws. These most versatile objects are significant in any building site, whether a residential or commercial space. However, these quick fasteners are often seen as the most underrated tool in home improvements despite their underlying importance.

Post your Requirement

And up until now, you have hardly ever noticed their significance and how they have made a difference. This article can be an eye-opener if you think there’s a universal screw for all your needs!

Let’s know about these fasteners that can help you choose the correct one according to your needs.

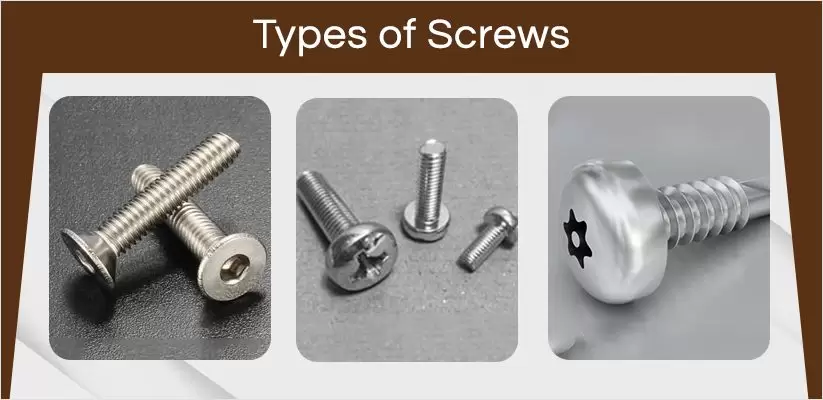

10 Types of screws that are common in the market.

1. Countersunk Screw

It is a type of screw used in lumber, where it is sunk with its head under the material’s surface, and it is later filled with filler or wood plug. Often, several other types of screws and bolts are also used for a similar purpose. It is quite easy to work with these, and one can even avail of a countersink screw set, where fasteners of different sizes are available.

Suggested Post: Types of Fasteners

It is generally used for joining two materials, where both of them are heavy-weight. Such pins help to hold on to the wall and makes a tight joint. If you are into interior stuff, having such a screw can help you showcase your stuff without installing too many of them and creating several holes on the wall. One does not even need to invest in a lot of filler as the holes are quite small, and thus easy to fill.

Where to install: Study desks, coffee tables, dining tables, ceilings, and interior decorations

Advantages of Countersunk Screw.

- Avoids accidents while working on the desk.

- It helps to increase the longevity of the wood.

- Keeps the screw hidden, which doesn’t ruin the aesthetics of an object.

2. Pan Head Screws

Similar to the oval head screws, these are majorly used as machine screws and have flat heads with two rounded sides. Being a machine screw, you can avail these in different shapes and sizes. It is generally used in the application of metal elements where the tapered side remains on the underside of the head and can be installed with just a screwdriver. There are three types of pan head fasteners – Phillips Pan Head, Square Pan Head, and Phillips Pan Framing.

The material used in them is usually zinc, coated in steel, which keeps it rust-proof and extends its longevity. However, the price range for these is not fixed, as various companies are coming up with a variety of product options.

Where to install Pan Head Screws: Cabinets, bumpers, desks, and braces

Advantages of Pan Head Screws.

- Holds the parts of machinery together.

- It can derive the electro-hydraulic servo valves.

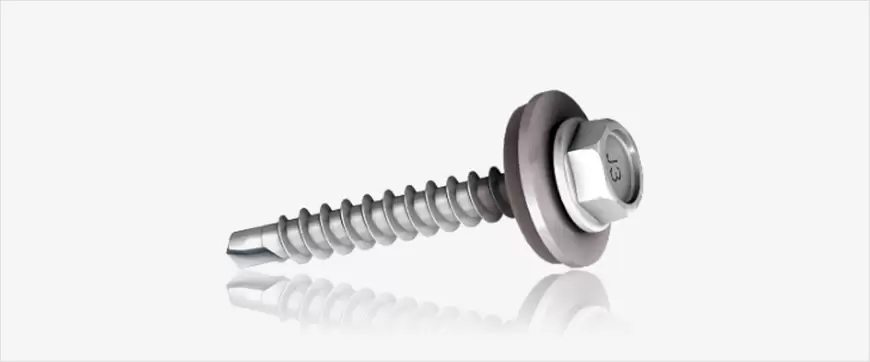

3. Self Drilling Screws

Made from hard stainless steel, which prevents rust and corrosion, the self-drilling screws comes with an added feature. These are primarily used in sheet metals and are easy to install in a pre-drilled hole. These are also the thread-cutting screws that can be used to cut the machine threads. However, there are a lot of configurations, which make them ideal for diverse usages like industrial and construction.

Moreover, these can also be widely used in the constriction of bricks, wood, and metal. But you need to make sure that the hole is not too large because the screw then will have nothing to hold on to or stay attached, especially if the material is soft like certain types of wood materials.

Where to install Self Drilling Screws: Table legs, hanging cabinets, pipe holders, bricks, hooks, and interiors

Advantages of Self Drilling Screws.

- Secure and easy to install.

- Maintains a tight hold on the objects.

- Serves as a durable option for the long run.

Buy Now Self Drilling Screws

4. Set Screws

Also known as the grub screw, the set screws are generally used to add extra security to the particular object. The object can be either attached from within or with another object. The usage of the nit is, however, optional in this case.

Unlike other screws, it is easy to identify because of its headless body. You can notice machinery threads all along its body and that too, in several dimensions. It is essential to keep an internal wrenching drive during the installation of the screw and to fasten it properly. Once it is installed, you can be assured that the object will not fall off because of the applied clamping force to the entire body of the object.

The best part about installing it is that you can reuse it without damaging the threads at all, also keeping the thread’s surface corrosion-proof. The application of these fasteners can be on soft as well as on the hard surfaces. So, investing in such screws will help you to install it both on wood as well as on metals.

Where to install Set Screws: Wooden surfaces, metal objects, brick walls

Advantages of Set Screws.

- It does not require any professional training or knowledge about angles to install it.

- Resistant to vibrations and sounds.

5. Threaded Screw

Threading is something that is present in all the screws and can be used on any surfaces and objects widely. It is designed with helical grooves, which help to dig the materials from the object, where the screw is put into.

However, there is an absolute difference between the two types of screws, that is, the fully threaded ones, and the partially threaded ones. The fully threaded ones come with a shaft, head, and a tip, while the partially threaded ones come with a shaft, which is not fully covered, and tip. Such screws undoubtedly provide more gripping to the object than any other type of screws.

Where to install Threaded Screw: Cabinets, planks, and walls

Advantages of Threaded Screw.

- It provides more strength and gripping to the object.

- It makes joining of two heavy objects easier to install.

- It comes with high durability.

Buy Now Threaded Screw

6. Wood screws

As the name implies, it is used to fasten a wooden workpiece. Brass, steel, and bronze are the most frequent materials used to make them. They come in a range of heads and have various threads. Their smooth shank and tapering point are perfect for penetrating the wood.

They come in different measurements for precision joinery and ease of control. Its diameter is thicker than the tip and thins slightly as we get closer to the top. These are offered with either partially or completely covered threads at the shank. Its’s head size varies depending on the application.

Whare to install wood screws: Hanging doors, wood planks & plywood.

Advantages wood screws.

- They easily begin and pierce the material because of their extremely sharp tip.

- They are pretty simple to use and inexpensive.

- They won’t budge like nails because of their far higher tensile strength.

7. Weld screws

To hold the object with a nut and washer, these must be welded to a metal surface with a shaft. By using a strong electrical impulse to melt a specially constructed spot on the screw and subsequently on the plate, the screw is first welded to the plate. They come in low carbon, stainless steel, heat-treated, and plated varieties.

To enable welding without drilling any holes, they protrude from the head. After that, a piece of metal placed on the metal base is connected to the welding stud. They are employed in the transportation, manufacturing, maritime, building, and aerospace sectors.

Whare to install weld screws: Steel Doors, aluminium doors & steel drawers

Advantages of weld screws.

- You can utilize them to establish a reliable hold.

- They keep foreign substances from leaking and contaminating the environment.

- They are a terrific way to establish a relationship that is quite durable.

8. Hex cap screws

They are hexagonal locks with six sides that have a perforated hex head on the head and a washer face on the bearing surface. Its six-sided shank or shaft has multiple applications. These kinds of fasteners are employed to join metal or wood. Its hexagonal head evenly distributes force for strong fastening and dependable security. They have chamfers and tight tolerances on their body dimensions.

These are primarily utilized in docks, bridges, road infrastructure, and buildings. Due to their narrow steel threads, they are perfect for interior home repair jobs. Additionally, the flat washer behind the head allows for precise application.

Whare to install hex cap screws: Metal joints, Metal doors & mechanical joints

Advantages hex cap screws.

- They have lever-arch systems that let you tighten things up with more force.

- Simple keys can be used to insert them.

- It can support a heavier load.

9. Thread cutting screws

They have sharp edges because the depth of the hole is somewhat more than the length of the fastener. This tool will prevent the metals from becoming trapped inside the apparatus. They frequently work with metal and wood. As they engrave their way into the substrate, they scrape away pieces of the material in which it is applied.

These are employed to lessen the accumulation of internal tool tensions, making them perfect for tough materials. It lacks a cutting edge, which makes it more challenging to work with materials with low compressive strength than a thread-forming type.

Whare to install thread cutting screws: Reinforced plastics & solid wall parts

Advantages thread cutting screws.

- It takes fewer tools to install; therefore, it can save you a lot of time.

- They offer a secure connection even when you only have access to one side of the item.

- The connection between the material and the fastener is tight.

10. Carriage bolts

These bolts are employed to secure wood to metal or metal to metal. They are a specific kind of hexagonal bolt used in woodworking, specifically for mounting metal to wood. These have a domed head design that can prevent one-sided loosening. An expanded head form prevents the bolt from being pulled through a wooden structure. Its shank is rounded all the way around, and its shallow mushroom head sets it apart from other bolts.

The carriage bolt’s domed head is made to prevent slipping from one side. If you use a domed head nut, you cannot unlock this fastener from the side. Additionally, the bolt cannot be dragged through the wooden structure due to the larger head.

Whare to install carriage bolts: Metal objects & wooden objects.

Advantages of carriage bolts.

- They are self-locking because the square shank piece prevents the bolt from rotating while it is being installed.

- When compared to ordinary bolts, they have a cleaner finish.

- It is less risky than a regular bolt when used in furniture applications. The rounded surface will prevent people from simply catching themselves.

To Wrap Up –

We hope that this article has revealed the various classifications and utility of these small but extremely important tools that are required to shape up our space! Now that you know the different types and functions of screws and where to install them go ahead and buy them according to your requirements.

Post A Comment