An engineered wood product that is made from wood particles is combined with other various binders and pressed into a sheet to create a particle board. It is mainly used as a construction material for furniture. It is highly versatile and affordable. It is known for its smooth surface and the uniformity that it offers. It is used as a substitute for plywood for ceilings, furniture, interior walls, underlayment, etc.

Post your Requirement

Some Types of Particle Boards

- Single Layer Particle Board

- Three-Layer Particle Board

- Melamine Particle Board

- Laminated Particle Board

- Graded Density Particle Board

- Veneered Particle Board

- Cement Bonded Particle Board

1. Single Layer Particle Board:

Single-layer particle boards are made out of similar-sized wood particles that have been crushed together. These types of boards are dense, that can be laminated but can not be painted. They are not waterproof even though they offer a feature of being water resistant. They are mainly used in the interiors of a space.

2. Three Layer Particle Board:

There are two layers of small wood particles and a layer of large wood particles in between these two the outer layers hold more adhesive than the inner layer. These wooden boards can be painted as they have a flat surface.

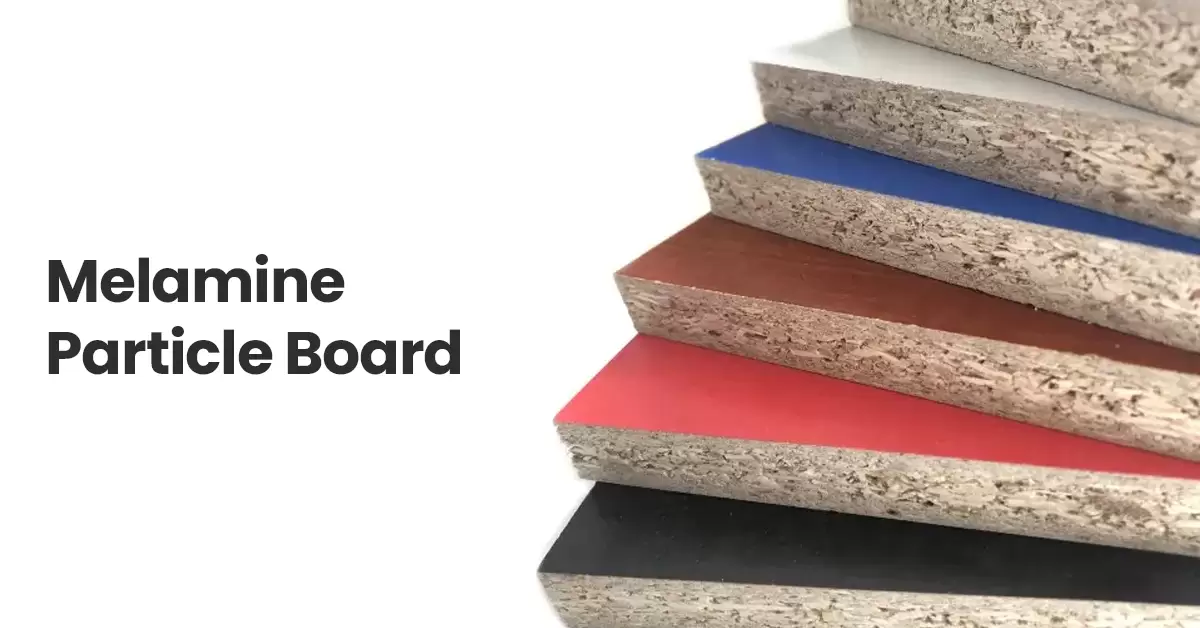

3. Melamine Particle Board:

In a melamine particle board, a sheet of melamine steep is pasted on the top surface of the particle board by using heat and pressure on it. These boards are water resistant as melamine-urea formaldehyde plaster is used with an emulsion of wax. These types of boards are durable and scratch-resistant. They are highly used in office furniture, wardrobes, wall cladding, modular kitchens, etc. They are available in a wide range of textures and color shades in the market so you can pick as per your requirements and preference.

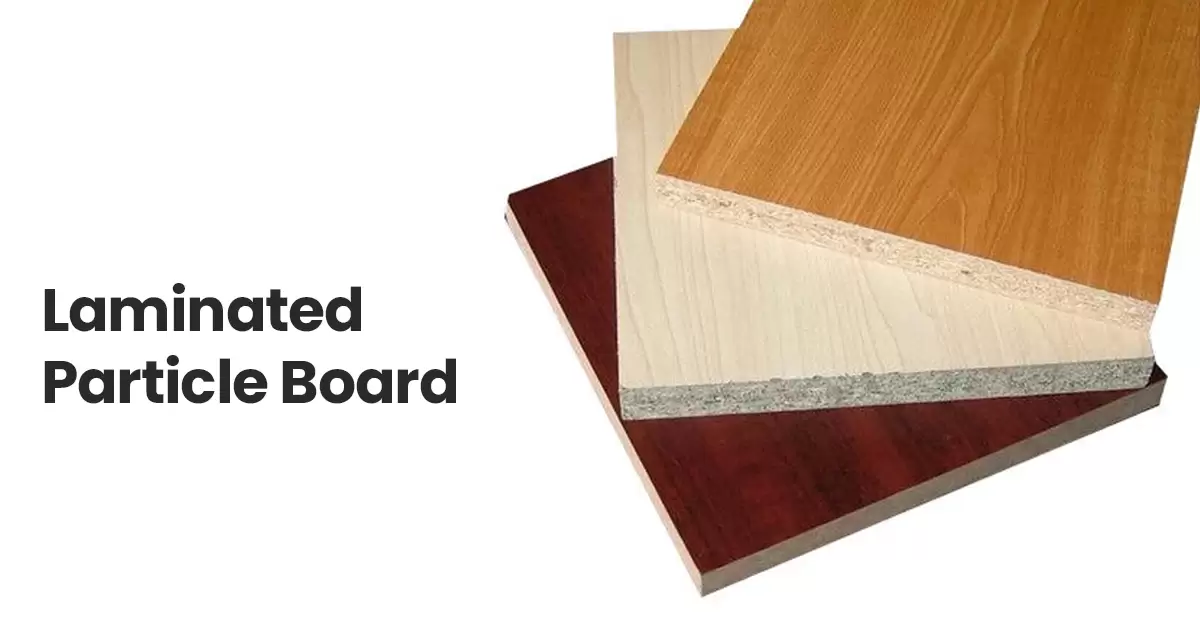

4. Laminated Particle Board:

These types of particle boards have a laminated sheet on their surface. Laminated particle boards are highly durable and are the number one choice in terms of aesthetics.

5. Graded Density Particle Board:

These types of particle boards have a layer of coarse wood chips incorporated in them. Two layers of wood particles are fixed in between one layer and the other. These are highly used to create cabinets and wooden furniture.

6. Veneered Particle Board:

Veneer is a thin piece of wood in a veneered particle board where it is attached to its surface. These types of particle boards resemble real wood. These are highly resistant to wrapping in comparison to other types of boards.

7. Cement Bonded Particle Board:

Cement is used as a bonding agent in these types of particle boards. They are fire, moisture, and rot-resistant. These are produced using cement, wood waste particles, wooden shavings, water, and sawdust. Due to its cement content, these boards are termite-resistant and are highly durable. These boards display shrinkage if there is a presence of moisture. These are highly used in creating fire-resistant furniture, interior and exterior walls, false ceilings, etc.

Uses of Particle Boards

- Particle Boards are used in furniture manufacturing like cabinets, tables, shelves, etc. They are used instead of solid wood to make it a cost-effective alternative. They can be shaped, laminated, and finished in a way to replicates other expensive woods.

- Particle boards are highly used to make cabinetry like kitchen cabinets and bathroom vanities. They have a smooth surface which provides a basis to other painted or laminated finishes.

- They are also used as a subflooring material in commercial, residential, and other areas. They provide a base for finished flooring materials like tile, hardwood, etc.

- They are highly used in the interior doors. They are lightweight and are comparatively lower in price than other solid wood doors. They are the number one choice for budget-conscious customers.

- They are majorly used to create storage shelves, closets and display shelves in retail stores. They can be customized and cut as per the size requirement and can be easily installed with the help of a nail, screw, and adhesive.

- They are used as a base in wall paneling in various buildings. They offer a smooth surface that can be easily painted or covered with a decorative finish like wallpaper, wood veneer, etc.

- They are used in numerous types of packaging materials. This is done because they are highly durable and powerful which helps in keeping the goods safe during shipping and transporting.

- They are used as temporary structures or as a base for decorative finishes like lamination or tile at various construction projects.

- These are highly used in partition walls as they are non-load-bearing and have good thermal insulation properties.

- The usage of cemented and laminated particle boards in false ceilings is markedly high due to thermal insulation properties.

- Veneer particle boards are used to create automobile parts, speaker boxes, and many other things.

Suggested Post: What is a Particle Board & Its Different Types

Properties of Particle Boards

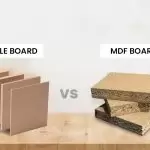

- As particle boards are made out of wood waste, they are considerably lightweight in comparison to plywood or MDF boards.

- In comparison with plywood and other natural wood, particle boards have higher density. But they have a lower density than MDF.

- They can not bear heavy weights as they are fragile.

- Moisture can easily make a particle board swell, crack, or discolor. It can cause damage to it in a very short amount of time.

- Coating a particle board with paint or primer can improve its resistance and strength.

- These boards have less strength which makes them less durable than plywood and solid wood. However, coating them can help in improving strength.

- They are used at places with high volume usage like recording studios as they have sound insulation properties.

- They can be made fire resistant by applying a layer of melamine on the top surface of it.

- As they are made up of recyclable materials, they are environmentally friendly.

Conclusion

Particle boards are a cost-effective alternative to solid wood and plywood. There are various types of particle boards available in the market as per their requirements and usage. They are highly used in making furniture. There are many other uses of particle boards which include creating flooring, doors, etc. While they have less strength when compared with other solid materials, they can be improved with the help of coating. All in all particle boards are a budget-friendly choice.

Read Also: Particle Board Vs. Plywood: Which Is Better For Your Project?

Post A Comment