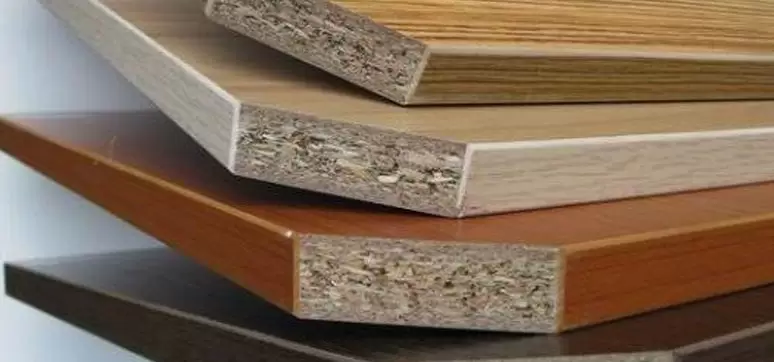

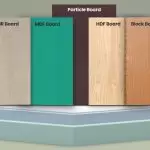

There are many kinds of engineered wood products used to make furniture and other wooden items for interior and external usage. Particle board is also one of the many engineered wooden products. It is also known as a low-density fiberboard or chipboard. The answer to the question of what is particle board is that it is a waste wood product made by binding wood chips, sawdust, or sawmill shavings with a synthetic resin or some other binder. Urea Formaldehyde is commonly used as a glue for binding wooden chips. Particle board can be used as a substitute for plywood for making furniture, the interior lining of walls and ceilings, as a substrate for countertops, floor decking, roof sheathing, underlayment interior decorative paneling, etc.

Post your Requirement

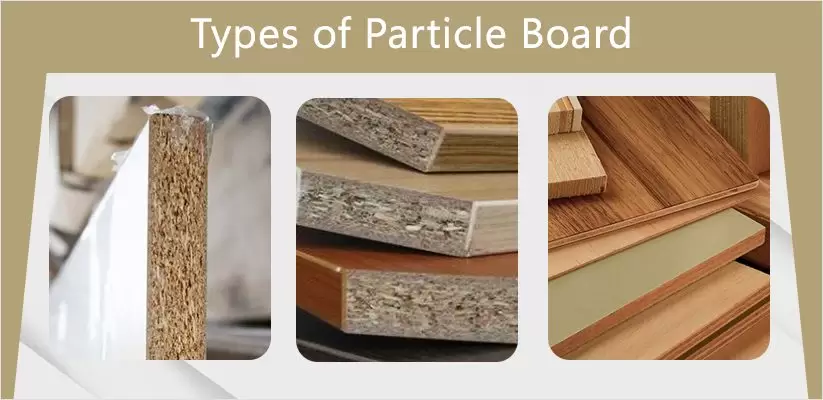

These are the Various Types of Particle Boards Available in the Market:

-

Single-layer Particle Board:

Single-layer particle board consists of wood particles of the same sizes which are pressed together. It is a flat and dense board that can be veneered or plastic laminated but not painted. This is a water-resistant type of particle board but is not waterproof. Single-layer particle boards are suitable for interior applications. -

Three-Layer Particle Board:

Three-layer particle board consists of a layer of large wood particles sandwiched between two layers made of very small and highly dense wood particles. The amount of resin in the outer layer is more than in the inner layer. The smooth surface of a three-layer particle board is ideal for painting.

-

Graded-Density Particle Board:

Graded-density particle board consists of a layer of coarse wood particles which is sandwiched between two layers made of fine wood particles. This type of particle board is used to make cabinets and wooden furniture.

-

Melamine Particle Board:

Melamine particle board is made by fixing a decor paper infused with melamine on the surface of the particleboard under high heat and pressure. The wood particles in a melamine particle board are bonded using melamine-urea formaldehyde resin and wax emulsion. This makes it water-resistant. Melamine particle board resists scratches. It comes in a plethora of colors and textures. Applications of melamine particle board include wall paneling, furniture, wall cladding, wardrobes, and modular kitchens.

-

Cement-Bonded Particle Board:

Cement-bonded particle board has magnesium-based cement or Portland cement as the bonding agent. Cement content is 60% while wooden particles such as wooden shavings, sawdust, and wood chips make up 20% of the composition. The remaining 20% is water. Due to the presence of cement, this type of particle board is resistant to moisture, fire, termites, and rot. High moisture resistance makes them suitable for constructing false ceilings, walls, and permanent coverings for concrete floors and walls for buildings located in areas with high humidity. They are also used for making fire-resistant furniture products.

-

Veneered Particle Board:

A veneered particle board means that it has a thin slice of wood called veneer attached to its surface. The veneered particle board appears like a natural wooden board. Furthermore, a veneered particle board is also more resistant to warping as compared to a conventional particle board.

-

Laminated Particle Board:

When a thin laminate sheet is attached to the surface of a plain particle board, it becomes a laminated particle board. A laminate sheet not only improves the aesthetics of the particle board but also increases its durability.

What is Particle Board Used For?

- Particle boards are used as coverings for hardwood floors. Particle boards protect the hardwood boards against scratches. In addition, particle boards are also used to make floors in temporary structures. Particle boards are also used as underlayment or base for wood flooring, parquet flooring, or carpets.

- Particleboards are commonly used to make the core of solid core doors and flush doors. Particleboard is a good core material for doors because it has a smooth and flat surface that binds with the door skin easily and exhibits a good screw-holding capacity for fixing hinges.

- Particle boards are used for making false ceilings. This is because particle boards provide good thermal insulation. They are also used as ceiling tiles in many types of buildings.

- Particle boards are used for making all kinds of furniture such as dressing units, tabletops, kitchen cabinets, wardrobes, bookshelves, shoe racks, beds, etc.

- Speakers are made of particle boards because they absorb sound. This is also the reason why particle boards are used on walls and floors of recording studios, auditoriums, and media rooms.

What Are The Advantages Of Particle Board?

- Particle board ensures low density that makes installation and handling easy.

- A cost-effective choice that is perfect for economical cost cabinetry.

- Utilizing repurposed wood, this product improves eco-consciousness.

- In thicker versions, it provides improved insulation against temperature differences and noise.

- When applied to interior walls and fences, it efficiently reduces noise and sound insulation.

- Splitting and warping are less likely when texture, surface, and density are constant.

- Efficient heat insulation is offered by thicker boards, which enhances energy efficiency and modernity.

- Particle boards are made of eco-friendly materials, ensuring sustainability and eco-consciousness.

- Economical wooden board, making it efficient for construction and furniture projects.

What Size Is Particle Board Available in?

Particle board is typically manufactured in thicknesses ranging from approximately 6mm to 26 mm or more with standard sheet dimensions of 4×8 feet, but it may be made in some sizes to meet a diverse range of purposes. Since it can be specifically cut to fit the diverse requirements of individual projects, its customizable features make it an outstanding choice for diverse furniture design and complex buildings.

Particle boards are designed and manufactured in typical sizes of 8 by 4 ft. and 7 by 4 ft, respectively. By the specifications for your cabinetry or any wooden storage solution, you can also find them in the thicknesses jotted down:-

- 9:00 mm

- 11:00 mm

- 12:00 mm

- 15:00 mm

- 17.00 mm

- 18.00 mm

- 25.00 mm

How Can McCoy Mart Help You Opt For Right Particle Board?

Are you searching out quality-made particle boards within budget? Looking for India’s top particle board brand? Or want to buy particle board in high quantity? We at Mccoy Mart have got you covered.

At McCoy Mart, we have a comprehensive selection of renowned particle board brands that have already been recognized as India’s top brands for providing quality particle boards. So what are you yet waiting for? Choose us and let us deliver best-in-class and modern particle board within budget and on time.

Suggested Read: MDF vs. Plywood vs. Particle Board

FAQ’S

Q:1 Is particle board cheaper than Plywood?

A:1 Undoubtedly yes, particle boards are more economical than plywood and other wooden boards. However, the choice of plywood may vary owing to various factors such as sturdiness, robustness, material selection, etc.

Q:2 Does the Particle board offer water resistance?

A:2 Yes, the particle board offers resistance to water, moisture, and dampness within budget and on time.

Q:3 How Durable is particle board?

A:3 Particle board hits a compromise between cost and usefulness, offering strength and robustness in indoor light-duty applications but weakness in damp, moisture, or intense usage.

Post A Comment