Just like your whole body can come apart without the presence of bones and joints, the entire house/office infrastructure can also fall apart if fasteners are not considered. However, we’ve often seen people not knowing the different types of fasteners and their benefits when it comes to fasteners.

Post your Requirement

So, before you select them in haste, let’s understand and get a good understanding of them.

Take a look at the 10 common types of fasteners used in our daily life.

1 Nuts & Bolts.

Nuts and bolts are connected, and you cannot use one leaving the other behind. Nuts acts as the applicant, and bolts, the applicator, that is, nuts puts everything together and holds it fastened in a frame. It is because of the friction of their threads that they are used together.

Types of nuts & bolts.

- Carriage Bolts: It comes in a dome-shaped and has a countersunk head shaped like a square. It is usually used to attach metal to wood and is often called a “coach” bolt too. The square part of the bolt, just under the head, is the part, which remains fastened to the metal. Without it, everything can fall apart.

- Hex Head Bolts: These have hexagonal-shaped heads and machine threads, which makes it easier to use in a tapped hole or, with a nut. As they have a unique head shape, make sure you are using a wrench while working with it.

- Shoulder Bolts: Also known as stripper bolts, the Shoulder bolts derive their name from their shape, which is like a shoulder located between the thread of the screw and the head of the part. It is quite easy to install, and once it is done, the non-threaded portion remains extended from the position.

- Cap Nuts: It comes with a domed top and derives its name from its shape. It has a hexagon shoulder in its sides and has continuous external machine thread lines inside, which help the screws to get fastened up ideally.

- Castle Nuts: Also called a slotted or castle nut, these nuts come with cotter pins, which helps to prevent the loosening of it from the material it is attached to. These are generally used with cotter pins and in the applications, which are usually low-torque such as when it comes to holding a wheel bearing to its lace.

Buy Now Nuts Bolts

2 Washers.

Looks typically like a disc, a washer is a thin plate with a hole in the middle and is generally used to distribute the load of the thread uniformly. It is usually used with a screw and helps it to remain fastened. Especially if you are going to install something heavyweight, washers can help to withhold it.

Types of washers.

- Backup Rivet Washers: If you want to install something with a larger diameter, then these washers can come to your help. They tend to give a tight hold to the objects and thus used to provide support to weighty objects. They can come as a great option when you want to pull-through through a rivet.

- Belleville Conical Washers: These are washers which gives an additional tension to the fastener and are used to increase deflection and load and depends significantly on the type of stack. They are also termed as lock washers and absorb vibration and tension, which in turn absorb vibration.

- Dock Washers: Considered generally as washers which can hold immense weight, and are often used while building docks. These are thick washers, which are mainly used during construction, especially heavy-duty. They are frequently recognized as fender washers too due to the small diameter hole that it has inside it.

- Fender Washers: These are called the round washers and have one small hole inside it. If you are looking for a washer that will give you an excellent bearing surface along with the fastener, then fender washers can come to your use because of their pull-through feature.

3 Screws.

Though similar to a bolt, screws help in vertical force division and thus helps to hold the object to the wall. They can be of various sizes and many materials and depends solely on your purpose.

Types of screws.

- Machine Screws: Machine screws, also known as bolts, come with a flat point and are often used in the tapped holes along with nuts and washers. These are also known as “stove bolts” or “stovers” and can be availed in variety because of their diverse drive types and heads.

- Hex Lag Screws: Also known as lag bolts, these are usually used to fix large pieces and hold weight. The head of these screws is the external hex and calls for a wrench during installation. It is greatly used for framing, machinery to wood floors, and other heavy-duty applications.

Suggested Post: Types of Screws

Buy Now Screws

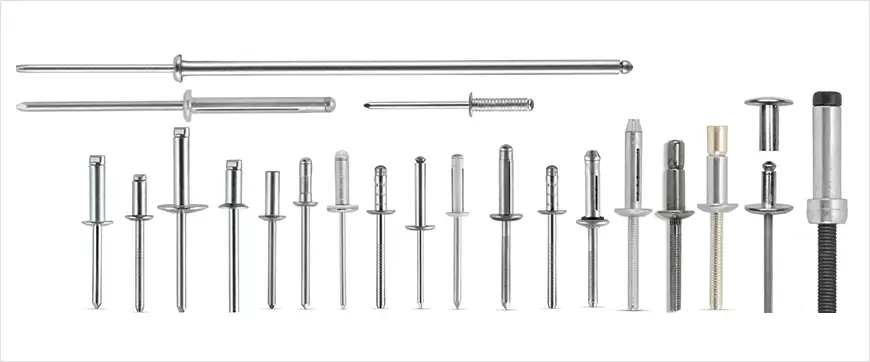

4 Rivets.

Working with metal objects, especially for industrial and security purposes, can be tricky. But with the existence of rivets, things have become quite easy to deal with. It looks like a short metal pin or bolt, and its headless end is beaten down to fix it in the place.

Types of rivets.

- POP Rivets: The POP Rivets, also called the blind rivets, are commonly used to join both the pieces which belong to a particular material. These are usually tubular and comes with a hat-like shape and a mandrel. While installing, it’s length is generally snapped off from the end.

- Large Flange POP Rivets: Also known as the oversize rivets, these are different than the standard rivets and usually come with a larger hat-like washer attached to it. They are often referred to as the blind rivets as well and are generally used for connecting both the parts of a particular material efficiently.

5 Nails.

Nails have been utilized since ancient times and have now become common. It is a short, flat-headed metal spike inserted into the wood to hold objects together or as a hook, unlike a screw or a nail, which lack threading on their bodies.

Types of nails.

- Common Nails: They are employed in building and construction. Since their large shank is dependable for robust support, they are frequently the first choice for framing and construction work.

- Box Nails: They are less strong and more suited to building boxes than framing houses since they have a narrower shank.

- Brad Nails: They are an excellent option for projects that call for a neatly finished appearance because they are more discreet than regular ones.

- Finishing Nails: Its thin and smooth look is frequently employed for finishing work. They are also more aesthetically pleasing due to their neater appearance.

- Drywall Nails: These are made with little rings around the shaft to make them more stable and less likely to slip.

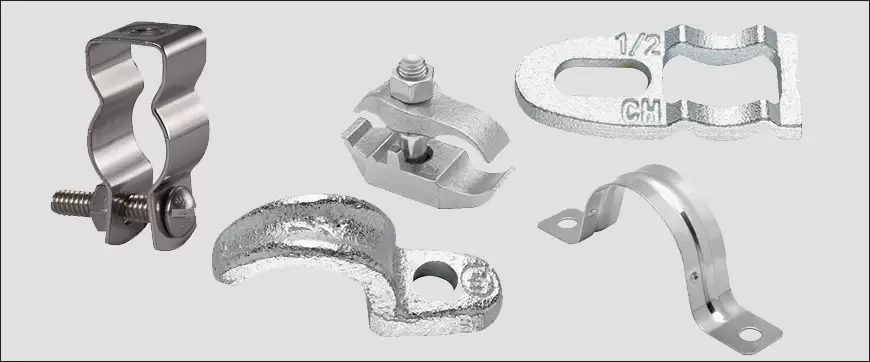

6 Clamps.

It is a fastening tool that applies internal pressure to tightly hold or bind things together to prevent movement or separation. It is a flexible tool that you can use to hold work firmly in place while it is being worked on. A few of their many uses include metal processing, building, welding, carpentry, and manufacturing furniture.

Types of Clamps.

- Dimide Clamp: It is a heavy-duty metalworking and welding clamp that combines power and speed with impact wrench compatibility.

- F or Bar Clamp: It is made to have a large opening capacity. A slider bar on the f-clamp makes it simple to change the opening capacity to fit a variety of applications.

- Quick grip or quick action clamps: These are increasingly common today since you can tighten them with just one hand by pumping the push handle.

- Locking clamps: They are quick and simple to operate, making them perfect for welding. These are perfect for woodworking and metalworking.

Buy Now Clamps

7 Pins.

These mechanical fasteners, which are unthreaded, are made to be placed into pre-drilled holes. They come in different sizes and materials, which you can use for various applications. These include small headless nails, pins with sharpened points for holding textiles while sewing, paper fasteners for pin boards, etc., and mechanical fastening.

Types of Pin.

- Dowel pin: It is only a simple solid cylinder placed via a hole. The hole typically has a minor interference fit, which allows the pin to be compressed and firmly in place by friction.

- Slotted pin: It is made from sheet material that has been partially rolled into a cylinder with chamfers on both ends. The chamfer allows it to drive the pin into a hole less than its relaxed diameter.

- Spiral or coiled roll pin: The sheet material is wound around itself more than once in this fastener. As a result, it is more durable than a slotted type.

- Grooved pin: Usually composed of steel, this tool has three grooves swaged along all or part of its length. It is also pushed into a small space.

Buy Now Pins

8 Wall plugs.

This plastic or fiber tool ensures screws can be properly fixed in a wall. With the help of these tools, objects like cabinets, frames, etc., can be firmly and indefinitely fastened to walls. It is advised to use a wall plug if a screw cannot penetrate the wall’s materials.

Types of wall plugs.

- Universal wall plug: This wall plug is helpful in various circumstances, including with hollow stones. It is recommended that you use it while paying close attention to the screw’s length and drill’s diameter.

- Hammer fixing plug: It can be compared to a pin and a nail screw together. You may just knock this tool into position once the wall has been drilled with the hole.

- Chemical anchor: You can use this tool as a final anchor for porous stones. You create a standard drill hole for this. The fastener must be inserted deeply into the hole until it is filled from end to end.

Buy Now Wall Plugs

9 Threaded Rod.

Also referred to as a stud, this tool is just a length of metal rod threaded throughout, therefore the alternate name “all thread.” This is one of the most adaptable solutions for connecting things because it comes in various types, lengths, and materials.

Types of Threaded Rod.

- Fully Threaded Stud Bolt: In these, the threading extends the entire length of the rod, enabling nuts and other fasteners to join fully anywhere along the bar.

- Double-Ended Threaded Rod or Double-Ended Threaded Bar: These have a portion of the stud threaded at each end but not through the center.

- Hollow Threaded Rod: This style has apertures at either end and is hollow the entire length of the stud. This enables the passage of cables and other components through the rod’s body.

- Fine Threaded Rod or Fine Pitch Threaded Rod: Typically, this type applies to studs with threads that are finer and more closely spaced than standard or coarse kinds.

10 Retaining Rings.

These metal fasteners provide a shoulder holding an assembly in place by slipping into a groove on a shaft, in a housing, or a bore. In mechanical power transmission assemblies, in particular, it serves as a shoulder to prevent the sub-component or assembly from slipping off the shaft or housing bore.

Types of Retaining Rings.

- Tapered Section Retaining Rings: They shrink symmetrically from the center to the free ends and maintain their circular shape when constricted or expanded within the parameters of typical use.

- Constant section retaining rings (snap rings): They have a consistent, uniform portion. In other words, the ring’s construction material is the same breadth over its whole circumference.

- Spiral retaining rings: These make 360° contact with the groove by being axially placed into housings/bores (internal) or onto shafts (external).

- Circular Push-On: It is frequently made of metal and has a toothed washer-like appearance. These are attached by applying pressure to the end of a shaft that has been grooved until the inner teeth of the nut engage the groove.

Now that we have guided you with the thorough different types of fasteners in detail, it will never be a problem for you to choose the right one for your needs. So, go ahead and select the one that fits your requirements.

Post A Comment